Services Email: cnkylt@aliyun.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 14 Author: Site Editor Publish Time: 2022-07-06 Origin: Site

A Tunisian manufacturer of control cables. They are looking for the similar of the following vertical die casting machine.

That can use our 12T or 20T vertical die casting machines to produce control cables. The control cable one side terminal or both side terminals need be cast with zinc/ zamak alloy as drawing designed structure.

"Die-casting machine is mainly used for die-casting zinc alloy parts of ф1-ф3.5mm steel wire. The main features of the equipment are: stable and reliable operation, high accuracy, fast speed, the machine adopts 45 # steel quenching and tempering plate, machine hinge, matching Precisely processed by the machining center, the shape materials are cut by computer water cutting, the appearance is beautiful and durable, the main column is made of 40Cr steel after heat treatment, the surface is made of chrome plating, the hydraulic pump is made of Taiwan SML vane pump, low noise, long life It has the advantages of being hot. The heating adopts electric heating tube to be combined with the pot body for heating. The heating system adopts PLC to control the automatic voltage regulation module to adjust the temperature with advanced PID control mode. The temperature difference is small, the heat preservation is good, and the life is long. , Aviation, medical and other industries brake line, cable line, connecting line, sofa joystick, the necessary equipment for the control line (rod)!

The machine is mainly composed of the following eight parts:

1. Melting system: from 9KW electric heating tube (total power of heating tube, PID control generally only takes more than half), then heat zinc alloy pot to 420 ℃,

2. Hydraulic system: composed of vane pump, oil circuit shunt plate, solenoid valve, etc.

3. Mould: Use the original Taiwan unified mould size!

4. Frame parts: mainly welded by 45 # steel plate and thickened square tube, and then derusted, and then subjected to high temperature tempering and shaping, in baking paint treatment, beautiful appearance and stain resistance;

5. Electric control device: It is mainly composed of touch screen, plc control Taiwan PID bidirectional thermostat, contactor, circuit breaker, Taiwan voltage adjustment module and other electrical components and cabinet body.

6. Cooling system: It consists of cooling pumps, pipes, joints, cooling boxes, etc. to cool the die-casting mold."

Vertical 12T & 20T die casting machines are widely used in many brake wires and control cables companies, they provide wires and cables for many famous car, bike, motorcycle factory. SHIMANO also use our machine to produce brake wires.

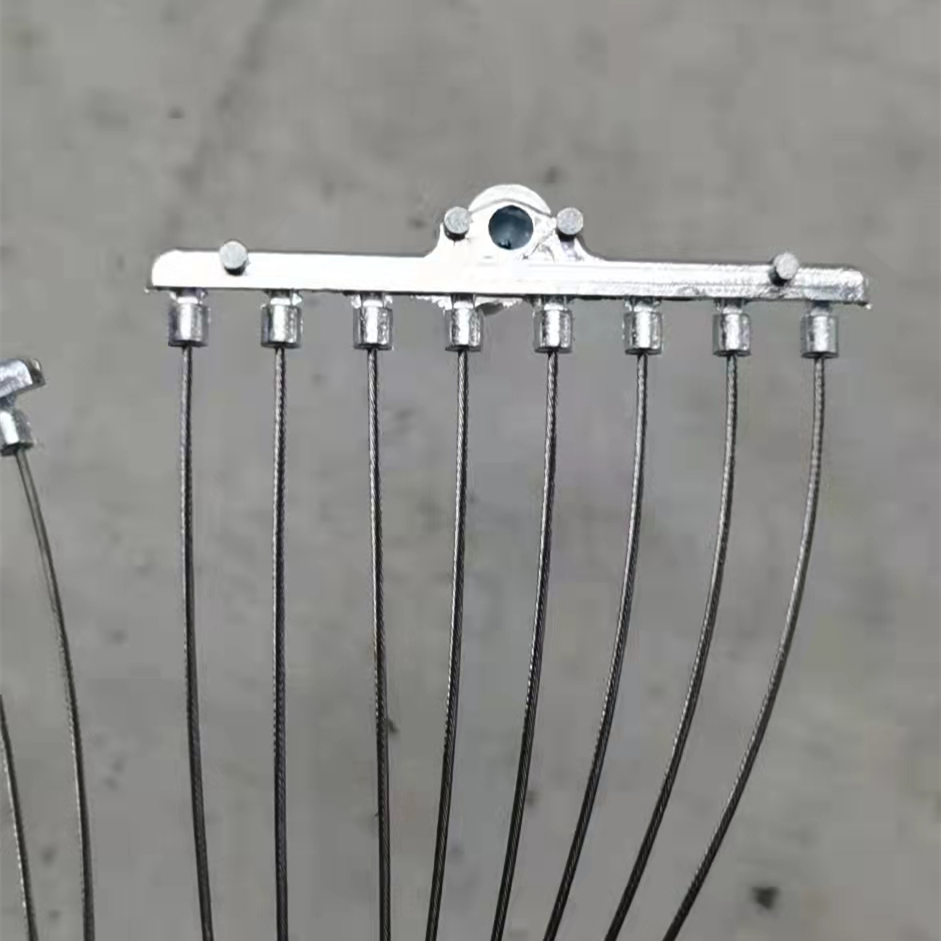

Photo shows SHIMANO special order vertical die castingmachine for brake wire/control cable zinc end making.

12T Vertical hot chamber die casting machine normally used to produce small zinc or lead alloy parts with insert parts which must be cast together with alloy.

Brake wires of car and bike: one mold 6pcs

metal shaped terminal pulling wires: one mold 2-6pcs

Name | Parameters | Name | Parameters | |

Locking Force | 120Kn | Motor Power | 3.75Kw | |

Tie Bars Inner Space | 190×220mm | Accumulator Capacity | 6.3L | |

Moving Platen Stroke | 100mm | Working Pressure | 8Mpa | |

Profiling Thickness | 110 – 190mm | Electric Heating Tube Power | 7.5Kw | |

Injection Pressure | 14Kn | Heater Power | 1Kw | |

Injection Stroke | 55mm | Oil Tank Capacity | 120L | |

Dosage of Fluid Metal per shot(Zn) | 130g | Machine Weight | About 1000Kg | |

Crucible Effective Capacity(Zn) | 70Kg | Machine Size | 120×90×210cm | |

Oil Pump | 28L/min | |||

Vertical machine consists of machine body, mold clamping mechanism, injection system, cooling system, melting furance, electric system etc. It adopts hydraulic drive, electric operation, and has manual and automatic operation.

Melting furance is heated by electrical heated tube, so its operation is easy, and it has big adjustment range and wide application scope. The brand of hydraulic valve, time relay, general relay, AC contactor, microswitch of this machine is domestic and oversea famous, so it is running stable and performing excellence. It runs efficiently after adjustment. This machine is suitable for zinc alloy, lead alloy and tin alloy casting of hardware, electrical appliance, tool industry etc.

To cast zinc terminal with wirerope. The manufacturing process need: die casting machine, die casting die, wireropes. Operator manual set wireropes on mold cavities. Normally 12T machine one time set 6 wireropes

The machine can be used to cast bike wire cable, motorcycle brake wire, car brake cable or wirerope with zinc end terminal.

About 12T Vertical hot chamber die casting machine price, or die casting mould, please feel free to email us: cnkylt@aliyun.com We will choose suitable machine types, suggestions of mould design, provide free die casting samples.

· Battery Spine Die Casting Machine

· Cold Chamber Die Casting Machine

· Hot Chamber Die Casting Machine

· Vertical Die Casting Machine

· Aluminum Die Casting Machine

· Magnesium Die Casting Machine

· Auto Parts Die Casting Machines

· Kitchen &Household Parts Die Casting Machines

· Lamps Light Parts Die Casting Machines

· Electric Vehicle Spare Parts Die Casting Machines

· Hardware, Jewelry, Clothing Accessories Die Casting Machines

· Tel-Communication Equipment Parts Die Casting Machines

· Garden Machinery & Electric Tools Parts Die Casting Machines

· Lead Acid Battery Terminal Bushing, Battery Positive Spine Grid Die Casting Machines

· Fishing Sinker Die Casting Machines

· Others