Services Email: cnkylt@aliyun.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Aluminum machining services to produce all kinds of precision aluminum CNC machined parts, such as: Aluminum milled & turned products.

Material: Aluminum alloys

Finishing: As demand, Polishing, Painting, Coating, Anodizing

Min Order: 1pcs)

| Machining Methods: | |

|---|---|

| Availability: | |

6061,6063,7075,5083

OEM, ODM

7616991090

- Full-services Custom Aluminum Machined Parts

- High quality precision Aluminum Machined Components

- Specialising in intricate, tight tolerance work

- Extensive experience and high customer satisfaction

Aluminum machining refers to the process of using specialized tools and techniques to shape, cut, or modify aluminum workpieces according to specific requirements or designs. It involves operations such as drilling, milling, turning, and finishing to create precise and functional aluminum components.

In KYLT, we work with aluminum by CNC machines to produce all kinds of precision CNC milling parts and CNC turning parts. of course, if needed, the aluminum parts maufacturing can involve machining processes:

| Welding | Stamping | WEDM | EDM | Turning |

| Milling | Drilling | Tapping | Laser cutting | Bending |

START YOUR NEW ALUMINUM MACHINING PROJECT, AND GET A FREE INSTANT QUOTE!

Contact Us: cnkylt@aliyun.com

CNC machining involves a series of steps that convert digital designs into physical parts with remarkable accuracy. The process begins with CAD (Computer-Aided Design) models, which are then translated into CNC code that guides the machine's tools. The CNC machine removes material from the aluminum block through milling, turning, drilling, and other operations, resulting in the creation of the desired part.

The use of aluminum in CNC machining offers several key benefits.

Aluminum's lightweight nature enhances fuel efficiency in industries like aerospace and automotive.

Its corrosion resistance ensures longevity in diverse environments.

Aluminum's malleability allows for intricate designs, making it suitable for complex components.

Aluminum machined parts find their applications across industries such as rail transit, automotive, electronics, and medical devices. In rail transit, aluminum components contribute to reduced overall train&subway weight. In the automotive sector, aluminum parts enhance vehicle performance and safety, leading to improved fuel economy.

KYLT provide Aluminum machining parts manufacturing services as per customers demand. Our Aluminum products reference:

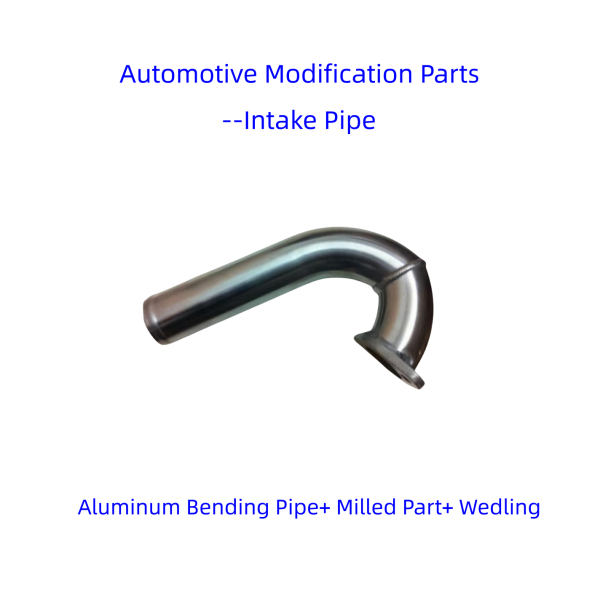

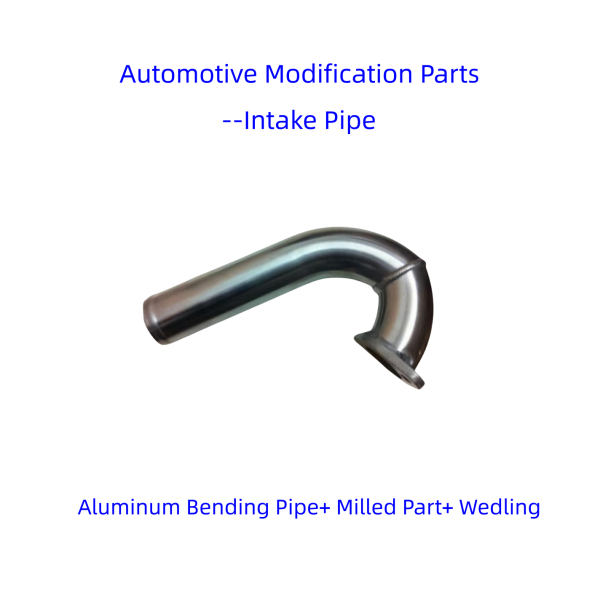

Modified car – Intake pipe making

Aluminum milled parts weld with Aluminum bended Pipes

Polishing, Powder coating etc

In the automotive industry, aluminum machined parts offer a compelling solution for enhancing vehicle performance and fuel economy. From engine blocks to suspension components, aluminum's high strength-to-weight ratio contributes to better handling and reduced energy consumption. CNC machining ensures precise manufacturing of these critical parts. Get A Free Qoute Now: cnkylt@aliyun.com

MEDICAL PARTS – Aluminum Turning parts

Aluminum Precision NC turned parts

Smooth bright machined surface

Precision is paramount in the medical field, and aluminum machined parts meet this requirement admirably. Medical devices such as surgical instruments, diagnostic equipment, and prosthetics often incorporate CNC-machined aluminum components due to their biocompatibility, durability, and intricate design capabilities. Get A Free Qoute Now: cnkylt@aliyun.com

SCREEN CONTROL PANEL BASE – Aluminum Milled parts

Aluminum Milling + Drilling + Tapping

CNC machined surface

The electronics sector relies on aluminum machined parts for their excellent thermal conductivity and electromagnetic shielding properties. Heat sinks, connectors, and enclosures for electronic devices are often crafted from CNC-machined aluminum. These parts help dissipate heat, extend device lifespan, and maintain optimal performance. Get A Free Qoute Now: cnkylt@aliyun.com

HAND WHEEL – Aluminum Turning parts

Aluminum die casting + Precision NC turned parts + Plating Pins +

Bakelite handle + Assemblying

Powder coating

The manufacturing sector itself relies on aluminum machined parts for the production of industrial machinery. From conveyor systems to production line components, aluminum's versatility and CNC machining's precision ensure the seamless operation of various manufacturing processes. Get A Free Qoute Now: cnkylt@aliyun.com

TOOLING & JIGS – Foaming Tooling, Checking Jigs or Fixtures

Aluminum block be milled as per design by CNC machines

Smooth or textured surface

Aluminum machined molds & fixtures are the custom-made device fabricated from aluminum through machining processes. Fixtures are designed to securely hold and position workpieces during manufacturing or assembly operations, ensuring accuracy and repeatability. Aluminum molds are used as fast molds of plastic injection molding, and Foaming molds. Get A Free Qoute Now: cnkylt@aliyun.com

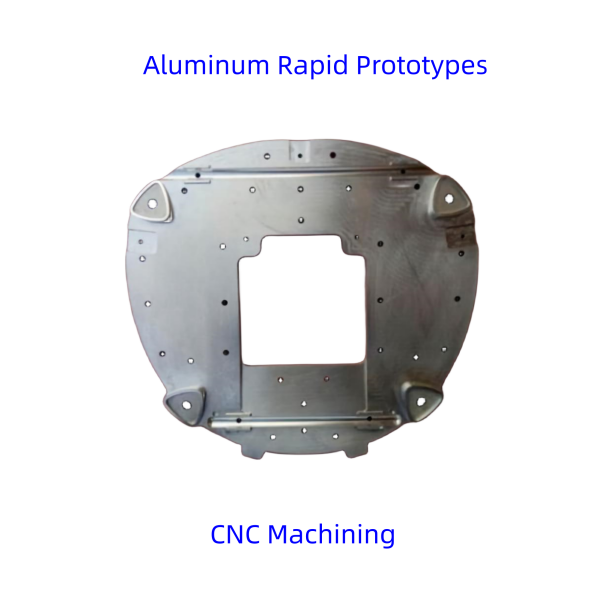

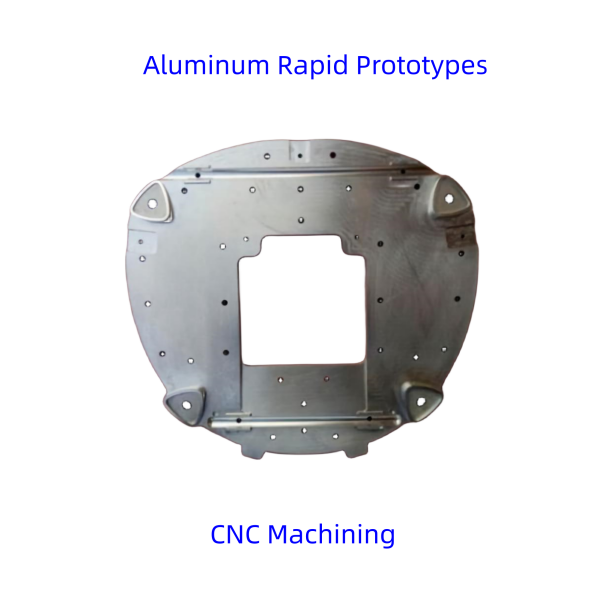

RAPID PROTOTYPE MAKING – Adopt kinds of machining methods to work with aluminum to got demand Aluminum Prototype.

Aluminum CNC milling or turning, WEDM, EDM, Wedling etc.

As machined, Anodizing, Painting, Coating, Plating etc

Aluminum rapid prototype manufacturing involves using 3/4/5 axis CNC machines to quickly produce prototypes or small batches of aluminum parts. It allows for rapid iteration and validation of designs before proceeding to full-scale production, saving time and costs in the development process. Get A Free Qoute Now: cnkylt@aliyun.com

DIE CASTING PARTS MACHINING – Aluminum die casting parts precision machining.

Machining Processes:

Drilled, tapped, lathing or milling machining.etc.

As machined, Painting, Powder Coating, Plating etc

Aluminum die casting parts machining refers to the process of performing secondary machining operations on aluminum parts that have been initially produced through die casting. These machining operations could include drilling, milling, tapping, or any other processes necessary to achieve the desired final dimensions, surface finish, or functional requirements of the aluminum parts. Get A Free Qoute Now: cnkylt@aliyun.com

KYLT 3,4,5 axis CNC machine shop capable of machined parts to customer specification. We can machine and accept the most common file formats including .dwg .dxf .iges .step .sat as well as .pdf files. If you don't see your file format here let us know. Please send us files to: cnkylt@aliyun.com We can accept both small and large run jobs of custom machined parts.

If you need Aluminum machined parts or prototypes, we are one of the most capable and affordable sources specializing in manufacturing precision machined parts. With over 10 years of experience, our CNC machine shop is able to produce parts that require innovative tooling and fixtures in a timely manner at competitive prices. We do CNC machining on 3, 4, 5 axis with all kinds of aluminum with 6061 and 7075 being the most used.

CNC milling machines

NC Lathes

WEDM

EDM

3-axis, 4-axis, and 5-axis CNC machines

Min. Qty: 1pcs.

Mass production: as per order

Short lead times are often available 2-3 days.

Standard lead time is 10-15days.

KYLT Precision Aluminum CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

- Full-services Custom Aluminum Machined Parts

- High quality precision Aluminum Machined Components

- Specialising in intricate, tight tolerance work

- Extensive experience and high customer satisfaction

Aluminum machining refers to the process of using specialized tools and techniques to shape, cut, or modify aluminum workpieces according to specific requirements or designs. It involves operations such as drilling, milling, turning, and finishing to create precise and functional aluminum components.

In KYLT, we work with aluminum by CNC machines to produce all kinds of precision CNC milling parts and CNC turning parts. of course, if needed, the aluminum parts maufacturing can involve machining processes:

| Welding | Stamping | WEDM | EDM | Turning |

| Milling | Drilling | Tapping | Laser cutting | Bending |

START YOUR NEW ALUMINUM MACHINING PROJECT, AND GET A FREE INSTANT QUOTE!

Contact Us: cnkylt@aliyun.com

CNC machining involves a series of steps that convert digital designs into physical parts with remarkable accuracy. The process begins with CAD (Computer-Aided Design) models, which are then translated into CNC code that guides the machine's tools. The CNC machine removes material from the aluminum block through milling, turning, drilling, and other operations, resulting in the creation of the desired part.

The use of aluminum in CNC machining offers several key benefits.

Aluminum's lightweight nature enhances fuel efficiency in industries like aerospace and automotive.

Its corrosion resistance ensures longevity in diverse environments.

Aluminum's malleability allows for intricate designs, making it suitable for complex components.

Aluminum machined parts find their applications across industries such as rail transit, automotive, electronics, and medical devices. In rail transit, aluminum components contribute to reduced overall train&subway weight. In the automotive sector, aluminum parts enhance vehicle performance and safety, leading to improved fuel economy.

KYLT provide Aluminum machining parts manufacturing services as per customers demand. Our Aluminum products reference:

Modified car – Intake pipe making

Aluminum milled parts weld with Aluminum bended Pipes

Polishing, Powder coating etc

In the automotive industry, aluminum machined parts offer a compelling solution for enhancing vehicle performance and fuel economy. From engine blocks to suspension components, aluminum's high strength-to-weight ratio contributes to better handling and reduced energy consumption. CNC machining ensures precise manufacturing of these critical parts. Get A Free Qoute Now: cnkylt@aliyun.com

MEDICAL PARTS – Aluminum Turning parts

Aluminum Precision NC turned parts

Smooth bright machined surface

Precision is paramount in the medical field, and aluminum machined parts meet this requirement admirably. Medical devices such as surgical instruments, diagnostic equipment, and prosthetics often incorporate CNC-machined aluminum components due to their biocompatibility, durability, and intricate design capabilities. Get A Free Qoute Now: cnkylt@aliyun.com

SCREEN CONTROL PANEL BASE – Aluminum Milled parts

Aluminum Milling + Drilling + Tapping

CNC machined surface

The electronics sector relies on aluminum machined parts for their excellent thermal conductivity and electromagnetic shielding properties. Heat sinks, connectors, and enclosures for electronic devices are often crafted from CNC-machined aluminum. These parts help dissipate heat, extend device lifespan, and maintain optimal performance. Get A Free Qoute Now: cnkylt@aliyun.com

HAND WHEEL – Aluminum Turning parts

Aluminum die casting + Precision NC turned parts + Plating Pins +

Bakelite handle + Assemblying

Powder coating

The manufacturing sector itself relies on aluminum machined parts for the production of industrial machinery. From conveyor systems to production line components, aluminum's versatility and CNC machining's precision ensure the seamless operation of various manufacturing processes. Get A Free Qoute Now: cnkylt@aliyun.com

TOOLING & JIGS – Foaming Tooling, Checking Jigs or Fixtures

Aluminum block be milled as per design by CNC machines

Smooth or textured surface

Aluminum machined molds & fixtures are the custom-made device fabricated from aluminum through machining processes. Fixtures are designed to securely hold and position workpieces during manufacturing or assembly operations, ensuring accuracy and repeatability. Aluminum molds are used as fast molds of plastic injection molding, and Foaming molds. Get A Free Qoute Now: cnkylt@aliyun.com

RAPID PROTOTYPE MAKING – Adopt kinds of machining methods to work with aluminum to got demand Aluminum Prototype.

Aluminum CNC milling or turning, WEDM, EDM, Wedling etc.

As machined, Anodizing, Painting, Coating, Plating etc

Aluminum rapid prototype manufacturing involves using 3/4/5 axis CNC machines to quickly produce prototypes or small batches of aluminum parts. It allows for rapid iteration and validation of designs before proceeding to full-scale production, saving time and costs in the development process. Get A Free Qoute Now: cnkylt@aliyun.com

DIE CASTING PARTS MACHINING – Aluminum die casting parts precision machining.

Machining Processes:

Drilled, tapped, lathing or milling machining.etc.

As machined, Painting, Powder Coating, Plating etc

Aluminum die casting parts machining refers to the process of performing secondary machining operations on aluminum parts that have been initially produced through die casting. These machining operations could include drilling, milling, tapping, or any other processes necessary to achieve the desired final dimensions, surface finish, or functional requirements of the aluminum parts. Get A Free Qoute Now: cnkylt@aliyun.com

KYLT 3,4,5 axis CNC machine shop capable of machined parts to customer specification. We can machine and accept the most common file formats including .dwg .dxf .iges .step .sat as well as .pdf files. If you don't see your file format here let us know. Please send us files to: cnkylt@aliyun.com We can accept both small and large run jobs of custom machined parts.

If you need Aluminum machined parts or prototypes, we are one of the most capable and affordable sources specializing in manufacturing precision machined parts. With over 10 years of experience, our CNC machine shop is able to produce parts that require innovative tooling and fixtures in a timely manner at competitive prices. We do CNC machining on 3, 4, 5 axis with all kinds of aluminum with 6061 and 7075 being the most used.

CNC milling machines

NC Lathes

WEDM

EDM

3-axis, 4-axis, and 5-axis CNC machines

Min. Qty: 1pcs.

Mass production: as per order

Short lead times are often available 2-3 days.

Standard lead time is 10-15days.

KYLT Precision Aluminum CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

When it comes to CNC machining of aluminum, selecting the right type of aluminum alloy is crucial to achieving optimal results. Different aluminum alloys offer varying properties that can influence factors such as machinability, strength, corrosion resistance, and thermal conductivity. Here are some common aluminum types used in CNC machining and their respective attributes:

| 1. | Aluminum 6061 | Aluminum 6061 is one of the most widely used aluminum alloys in CNC machining. Known for its excellent machinability, it offers good strength-to-weight ratio, making it suitable for a range of applications. It can be easily welded and has good corrosion resistance. Aluminum 6061 is commonly used in aerospace components, automotive parts, and general machinery. |

2. | Aluminum 7075 | Aluminum 7075 is recognized for its high strength and exceptional toughness. While its machinability is slightly lower than some other alloys, it is still commonly used in CNC machining due to its excellent mechanical properties. It finds applications in industries such as aerospace, defense, and sports equipment. |

3. | Aluminum 5052 | Aluminum 5052 is known for its corrosion resistance, making it suitable for marine and outdoor applications. It offers good formability and weldability, and its moderate strength makes it versatile for various machining projects. This alloy is often used in sheet metal fabrication, electronics, and architectural components. |

4. | Aluminum 6063 | Aluminum 6063 is favored for its extrudability and formability. It is often used in intricate shapes and profiles due to its ease of shaping. While it might not possess the same strength as some other alloys, it finds applications in architectural and decorative components, as well as in the production of heat sinks. |

5. | Aluminum 2024 | Aluminum 2024 is valued for its high strength-to-weight ratio and excellent fatigue resistance. It is commonly used in aerospace applications, particularly for components that require strength while minimizing overall weight. However, its machinability can be challenging, requiring appropriate tooling and techniques. |

6. | Aluminum 5083 | Aluminum 5083 is primarily used in marine applications due to its exceptional corrosion resistance in saltwater environments. It also offers good weldability and moderate strength. This alloy is often chosen for CNC machining parts in shipbuilding and naval industries. |

7. | Aluminum 2011 | Aluminum 2011 is known for its free-machining properties, making it ideal for parts that require intricate details and high-speed machining. It offers good strength and is often used in applications where precision and efficient machining are paramount. |

8. | Aluminum 3003 | Aluminum 3003 is primarily used in sheet metal applications and offers good formability and weldability. It is commonly used in cooking utensils, chemical equipment, and decorative trim. |

9. | Aluminum 6082 | Aluminum 6082 is similar to 6061 in terms of machinability and strength. It offers good corrosion resistance and is often used in structural applications, transportation, and general machinery. |

10. | Aluminum 7050 | Aluminum 7050 is known for its high strength and resistance to stress corrosion cracking. It is commonly used in aerospace applications where strength and toughness are critical. |

Selecting the appropriate aluminum alloy for CNC machining depends on the specific requirements of the project, including mechanical properties, environmental factors, and intended use. By understanding the attributes of different aluminum types, manufacturers can make informed decisions to produce high-quality machined parts.

Several factors influence the quality of aluminum machined parts. Cutting speed, tool selection, material properties, and cooling mechanisms all play vital roles in achieving precise dimensions and surface finishes. CNC machines must be programmed with optimal parameters to ensure high-quality outcomes.

Compared to traditional machining, CNC machining offers distinct advantages. It provides greater automation, reducing the need for manual intervention and minimizing human errors. CNC machining also enables higher precision and consistency, resulting in parts with minimal variations.

One of the standout features of CNC-machined aluminum parts is their customization potential. Manufacturers can easily adapt designs to meet specific requirements, producing parts with intricate geometries that would be difficult to achieve using conventional methods.

Precision and tight tolerances are critical in industries like aerospace and medical devices. CNC machining ensures exceptional accuracy, meeting the demanding requirements of such sectors.

CNC machining offers a compelling balance between cost-effectiveness and time efficiency. While initial setup and programming may take time, the actual machining process is swift, resulting in reduced lead times.

In the realm of manufacturing, aluminum machined parts produced through CNC machining represent the pinnacle of precision and versatility. The marriage of aluminum's exceptional properties with the capabilities of CNC technology has propelled industries forward, enabling the creation of intricate components that drive progress. Whether in aerospace, automotive, electronics, or various other sectors, the role of aluminum machined parts is undeniable.

LET'S START A NEW ALUMINUM MACHINED PROJECT, AND GET A FREE INSTANT QUOTE!

Contact Us: cnkylt@aliyun.com

When it comes to CNC machining of aluminum, selecting the right type of aluminum alloy is crucial to achieving optimal results. Different aluminum alloys offer varying properties that can influence factors such as machinability, strength, corrosion resistance, and thermal conductivity. Here are some common aluminum types used in CNC machining and their respective attributes:

| 1. | Aluminum 6061 | Aluminum 6061 is one of the most widely used aluminum alloys in CNC machining. Known for its excellent machinability, it offers good strength-to-weight ratio, making it suitable for a range of applications. It can be easily welded and has good corrosion resistance. Aluminum 6061 is commonly used in aerospace components, automotive parts, and general machinery. |

2. | Aluminum 7075 | Aluminum 7075 is recognized for its high strength and exceptional toughness. While its machinability is slightly lower than some other alloys, it is still commonly used in CNC machining due to its excellent mechanical properties. It finds applications in industries such as aerospace, defense, and sports equipment. |

3. | Aluminum 5052 | Aluminum 5052 is known for its corrosion resistance, making it suitable for marine and outdoor applications. It offers good formability and weldability, and its moderate strength makes it versatile for various machining projects. This alloy is often used in sheet metal fabrication, electronics, and architectural components. |

4. | Aluminum 6063 | Aluminum 6063 is favored for its extrudability and formability. It is often used in intricate shapes and profiles due to its ease of shaping. While it might not possess the same strength as some other alloys, it finds applications in architectural and decorative components, as well as in the production of heat sinks. |

5. | Aluminum 2024 | Aluminum 2024 is valued for its high strength-to-weight ratio and excellent fatigue resistance. It is commonly used in aerospace applications, particularly for components that require strength while minimizing overall weight. However, its machinability can be challenging, requiring appropriate tooling and techniques. |

6. | Aluminum 5083 | Aluminum 5083 is primarily used in marine applications due to its exceptional corrosion resistance in saltwater environments. It also offers good weldability and moderate strength. This alloy is often chosen for CNC machining parts in shipbuilding and naval industries. |

7. | Aluminum 2011 | Aluminum 2011 is known for its free-machining properties, making it ideal for parts that require intricate details and high-speed machining. It offers good strength and is often used in applications where precision and efficient machining are paramount. |

8. | Aluminum 3003 | Aluminum 3003 is primarily used in sheet metal applications and offers good formability and weldability. It is commonly used in cooking utensils, chemical equipment, and decorative trim. |

9. | Aluminum 6082 | Aluminum 6082 is similar to 6061 in terms of machinability and strength. It offers good corrosion resistance and is often used in structural applications, transportation, and general machinery. |

10. | Aluminum 7050 | Aluminum 7050 is known for its high strength and resistance to stress corrosion cracking. It is commonly used in aerospace applications where strength and toughness are critical. |

Selecting the appropriate aluminum alloy for CNC machining depends on the specific requirements of the project, including mechanical properties, environmental factors, and intended use. By understanding the attributes of different aluminum types, manufacturers can make informed decisions to produce high-quality machined parts.

Several factors influence the quality of aluminum machined parts. Cutting speed, tool selection, material properties, and cooling mechanisms all play vital roles in achieving precise dimensions and surface finishes. CNC machines must be programmed with optimal parameters to ensure high-quality outcomes.

Compared to traditional machining, CNC machining offers distinct advantages. It provides greater automation, reducing the need for manual intervention and minimizing human errors. CNC machining also enables higher precision and consistency, resulting in parts with minimal variations.

One of the standout features of CNC-machined aluminum parts is their customization potential. Manufacturers can easily adapt designs to meet specific requirements, producing parts with intricate geometries that would be difficult to achieve using conventional methods.

Precision and tight tolerances are critical in industries like aerospace and medical devices. CNC machining ensures exceptional accuracy, meeting the demanding requirements of such sectors.

CNC machining offers a compelling balance between cost-effectiveness and time efficiency. While initial setup and programming may take time, the actual machining process is swift, resulting in reduced lead times.

In the realm of manufacturing, aluminum machined parts produced through CNC machining represent the pinnacle of precision and versatility. The marriage of aluminum's exceptional properties with the capabilities of CNC technology has propelled industries forward, enabling the creation of intricate components that drive progress. Whether in aerospace, automotive, electronics, or various other sectors, the role of aluminum machined parts is undeniable.

LET'S START A NEW ALUMINUM MACHINED PROJECT, AND GET A FREE INSTANT QUOTE!

Contact Us: cnkylt@aliyun.com