Services Email: cnkylt@aliyun.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Are you looking for a reliable and efficient way to produce high-quality aluminum parts in large quantities? Look no further than aluminum die casting machines! These machines are the cornerstone of the aluminum parts production process, and their use has revolutionized the way manufacturers approach aluminum part manufacturing. In this article, we will dive deep into the world of aluminum die casting machines, exploring their history, the technology behind their operation, and their many benefits.

Aluminum die casting machines are powerful pieces of equipment that use high-pressure injection to create complex aluminum parts. These machines work by heating aluminum to its melting point and injecting it into a steel die mold using a high-pressure plunger. The molten aluminum cools and solidifies inside the mold, taking on the shape of the die cavity. The resulting parts are highly accurate and precise, with very little post-processing needed.

All Aluminum pressure die casting machines are Cold Chamber type. So, all aluminum die casting machines are cold chamber die casting machines.

Aluminum die casting machines use a combination of heat, pressure, and precision to create complex aluminum parts. Here's how the process works:

The aluminum is melted in a furnace, typically using natural gas or electricity.

Once the aluminum reaches its melting point, it is injected into a steel die mold using a high-pressure plunger.

The molten aluminum quickly cools and solidifies inside the mold, taking on the shape of the die cavity.

The die is opened, and the finished part is removed.

LZ die-casting machinery is one Horizontal cold chamber pressure die casting machine manufacturer in china. We have 150T, 160T, 220T, 268T, 300T, 350T, 400T, 550T, 700T, 850T, 1100T, 1300T Aluminum die casting machines for sale.

Aluminum die casting machines offer a wide range of benefits, including:

High accuracy and precision: Aluminum die casting machines can create highly accurate and precise parts with very little post-processing needed.

Efficient production: Aluminum die casting machines can produce large quantities of parts quickly and efficiently.

Versatility: Aluminum die casting machines can be used to create complex parts with intricate geometries.

Low cost: Aluminum die casting machines are relatively inexpensive compared to other manufacturing methods, making them an attractive option for businesses of all sizes.

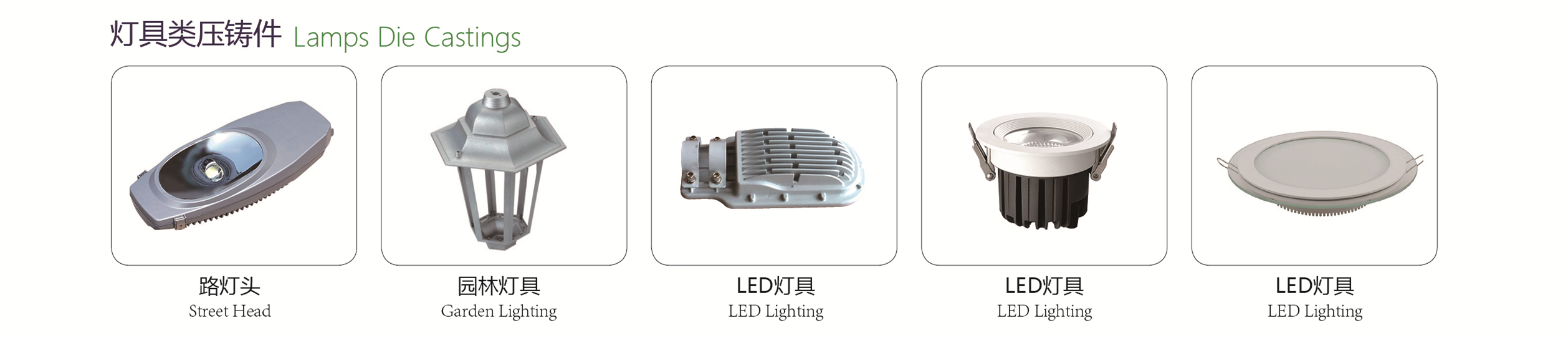

What Applications are Aluminum Die Casting Machines Used For? Aluminum Cold chamber Die Casting Machines are widely used to producet die casting parts of Aluminum alloy, ZAMAK/Zinc alloy, Magnesium alloy, Copper alloy and Lead alloy. All those metal alloys be cast with high pressure.

There are two kinds aluminum alloy die casting working process: Manual, Automatic.

Aluminum die casting machinery production line main consist two sections: horizontal cold chamber die-casting machine, aluminum melting furnace. With a die casting mould, the manual aluminum die casting process is established.

Automatic aluminum die casting process consists: Aluminum melting furnace, Metal ladling machine, Aluminum die casting machine, Spraying machine, die casting parts pick-up machine.

Melting furnace heats by electric or gas, ladling machine ladles molten aluminum alloy from furnace to die casting machine cold chamber. Injection mechanism shot liquid aluminum alloy into mold cavities. Mold open, solid aluminum die cast parts be ejected out from mold cavities. Die casting parts pick-up machine take out the metal parts. Sprayer cools and lubricates the mold cavity.

There are many different types of aluminum alloys that are used in die casting, each with its own unique properties and characteristics. Some of the most commonly used alloys include:

A380: This is a popular alloy that offers a good combination of strength, ductility, and heat resistance.

A413: This alloy has excellent corrosion resistance and is often used for parts that will be exposed to harsh environments.

A360: This alloy has good castability and is often used for intricate parts that require high detail.

ADC12: This is a high-strength alloy that is often used for automotive parts and other applications that require high strength and durability.

In china, we normally use A380 & ADC12 in aluminum die casting products manufacturing.

Get a FREE quotation of your aluminum die casting part price, please email: cnkylt@aliyun.com

Aluminum die casting machines are a key component of the modern manufacturing process, allowing businesses to produce high-quality aluminum parts quickly and efficiently. With their accuracy, precision, and versatility, these machines are an essential tool for businesses of all sizes looking to stay competitive in today's fast-paced manufacturing landscape.

KYLT Industrial is your trustable Aluminum Die casting machines manufacturer, supplier & factory. More information of Aluminum die casting machines price or technical parameters, please email us: cnkylt@aliyun.com

Aluminum die casting machines have a rich history, with the first patent for a die casting machine dating back to the mid-1800s. However, it wasn't until the early 1900s that these machines began to see widespread use in manufacturing. The invention of the hot-chamber die casting machine in 1914 made the process more efficient, and by the 1930s, die casting was a popular method for producing a variety of metal parts.

As technology continues to advance, the future of aluminum die casting machines looks bright. New developments in machine automation, artificial intelligence, and robotics are making it easier than ever to produce high-quality aluminum parts quickly and efficiently. Additionally, the use of sustainable materials and renewable energy sources in the production process is becoming increasingly important, and aluminum die casting machines are well-positioned to meet these challenges.

A1. Die casting is a process used to produce metal parts by injecting molten metal into a mold cavity under high pressure.

A2. Aluminum die casting machines are specifically designed to work with aluminum alloys, while other types of die casting machines may work with other metals.

A3. Aluminum die casting machines are used to produce a wide range of parts, from small, intricate components to large, complex structures. Some common applications include automotive parts, aerospace components, and consumer goods.

A4. Benefits of aluminum die casting machines include high accuracy and detail, fast production times, versatility, and cost-effectiveness.

A5. There are many different types of aluminum alloys used in die casting, including A380, A413, A360, and ADC12.

A6. Aluminum die casting machines are increasing efficiency, reducing costs, allowing for increased design flexibility, and driving advancements in technology.

A7. Aluminum die casting machines can be used to produce a wide range of parts, including automotive parts, aerospace parts, and consumer electronics parts.

A8. Parts produced with aluminum die casting machines are highly accurate and precise, with tolerances as low as 0.01mm.

A9. Aluminum die casting machines offer several advantages over other manufacturing methods, including high accuracy and precision, efficient production, versatility, and low cost.

A10. The time it takes to produce a part with an aluminum die casting machine varies depending on the size and complexity of the part, but it typically takes just a few minutes.

A11. Aluminum die casting machines are relatively environmentally friendly, as they produce very little waste and use minimal energy compared to other manufacturing methods.

A12. Yes, aluminum die casting machines can produce parts with a range of surface finishes, including smooth, textured, and painted finishes.