Services Email: cnkylt@aliyun.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Materials: | |

|---|---|

| Tonnages: | |

| Mold service: | |

| Type: | |

| PLC: | |

| Working period: | |

| Original: | |

| Availability: | |

180T~2000T

LZ

8454301000

Aluminum die casting machine widely used to produce cast aluminum parts for applications in various end-user sectors, such as Household Electric Appliances, Kitchen appliances, automotive, agriculture machinery etc.

High pressure aluminum alloy die casting machine accounted for about 70% of the aluminum die casting machinery market share.

Bühler, Toshiba, Dynacast, Oskar , Idra Group are the world famous top five aluminium die casting machinery manufacturers.

Normally there are 2kinds die casting machines: Horizontal type, Vertical type

Horizontal die casting machine has cold chamber and hot chamber version.

Aluminum pressure die casting machine is horizontal cold chamber type. For big scale and heavy weight zinc alloy die cast parts also use horizontal cold chamber die casting machine.

Horizontal hot chamber die casting machine is used to cast zinc, lead, tin alloy parts.

Vertical die casting machine most is to cast low melting point metal alloy, such as zinc, lead, tin alloys. The die cast parts features, which have insert parts to cast with alloy together. And Vertical die cast machine is easy for set insert parts in mold cavities.

LZ die-casting machinery is one Horizontal cold chamber pressure die casting machine manufacturer from china. We have 150T, 160T, 200T, 280T, 300T, 350T, 400T, 550T, 700T, 800T, 1100T. 1300T, 2000T for sale.

Cold chamber Die Casting Machines suitable for Aluminum alloy, Zinc alloy, Magnesium alloy, Copper alloy and Lead alloy casting. All those metal alloys be cast with high pressure. Molten metal be forced into mold cavities through cold chamber by plunger.

There are two kinds aluminum alloy die casting working process: Manual, Automatic.

Aluminum die casting machinery production line main consist two sections: horizontal cold chamber die-casting machine, aluminum melting furnace. With a die casting mould, the manual aluminum die casting process is established.

Video of manual die casting method:

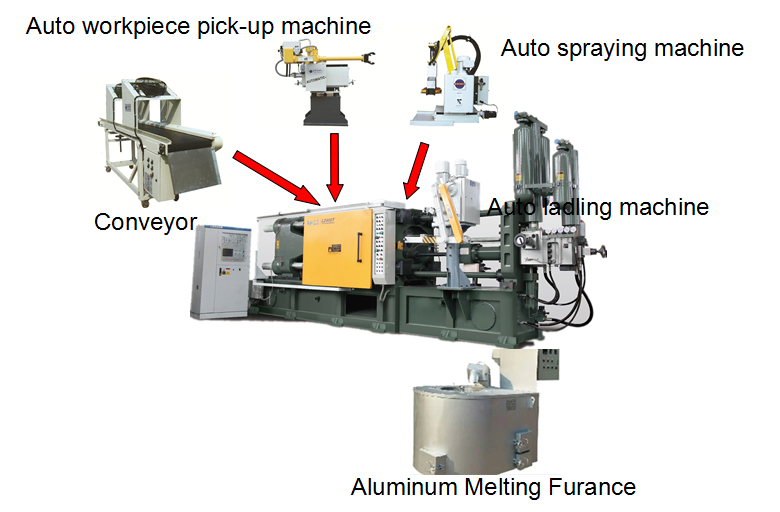

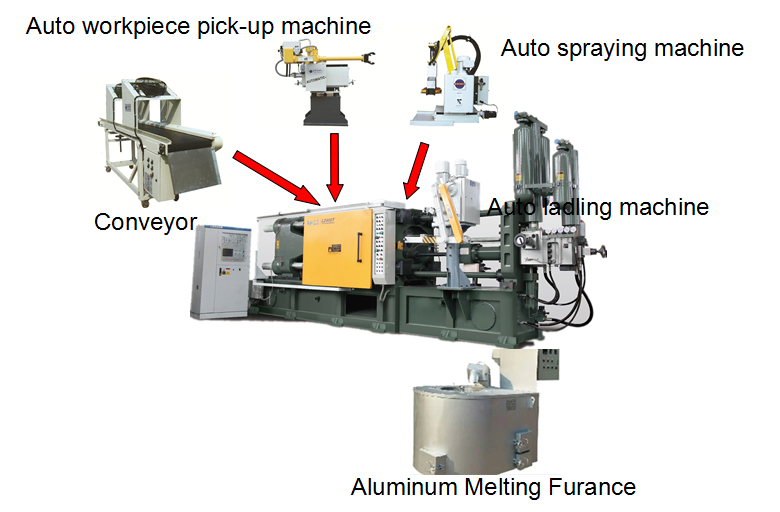

Automatic aluminum die casting process consists: Aluminum melting furnace, Metal ladling machine, Aluminum die casting machine, Spraying machine, die casting parts pick-up machine.

Melting furnace heats by electric or gas, ladling machine ladles molten aluminum alloy from furnace to die casting machine cold chamber. Injection mechanism shot liquid aluminum alloy into mold cavities. Mold open, solid aluminum die cast parts be ejected out from mold cavities. Die casting parts pick-up machine take out the metal parts. Sprayer cools and lubricates the mold cavity.

Video of Aluminum automatic die casting working process:

https://www.youtube.com/shorts/npYbgva3NK8

Aluminum die casting machine price or cost depends on die casting manufacturers capital budget and demand. Small tonnage die casting machine and manual die casting process are cheap.

| No. | ITEM | UNIT | LZ150/160 | LZ180 | LZ200 | LZ268 |

| 1 | Clamping Force | KN | 1500/1600 | 1800 | 2000 | 2680 |

| 2 | Inner space between tie bars (H*V) | mm | 440×440 | 480×480 | 490×490 | 540×540 |

| 3 | Die Stroke | mm | 340 | 380 | 380 | 450 |

| 4 | Die Thickness | mm | 200~550 | 200~550 | 200~550 | 250~650 |

| 5 | Ejection Stroke | mm | 80 | 80 | 80 | 110 |

| 6 | Ejection Force | KN | 100 | 110 | 110 | 150 |

| 7 | Injeciton Force | KN | 110~190 | 105~230 | 105~236 | 133~280 |

| 8 | Injection position (center is "0",down is "-") | mm | 0,-70,-140 | 0,-140 | 0,-140 | 0,-160 |

| 9 | Dia. of shot sleeve | mm | 40,50,60 | 50,60,70 | 50,60,70 | 50,60,70 |

| 10 | Dia.of Injection chamber flange | mm | 110 | 110f7 | 110f7 | 110f7 |

| 11 | Over height of flange | mm | 10-0.05 | 10-0.05 | 10-0.05 | 12-0.05 |

| 12 | Dosage of fluid metal pershot | kg | 1.8 | 2.5 | 2.5 | 3.2(Al). 2.3(Mg) |

| 13 | Projected area | cm | 105~550 | 171~666 | 172~660 | 196~800 |

| 14 | Injection pressure | Mpa | 36~149 | 27.3~117 | 28~118 | 35~143 |

| 15 | Dry cycle | s | 7 | 7 | 7 | 10 |

| 16 | Oil tank capacity | L | 450 | 550 | 650 | 750 |

| 17 | Motor power | KW | 11 | 11 | 15 | 18.5 |

| 18 | Machine sizes (L*W*H) | M | 5.1×1.2×2.2 | 5.7×1.3×2.4 | 5.8×1.25×2.4 | 6.4×1.6×2.8 |

(Remark:The company keeps the right to revise above parameters, If there is any alterations, advance notice won't be given then.)

| No. | ITEM | UNIT | LZ300 | LZ350 | LZ400 | LZ550 |

| 1 | Clamping Force | KN | 3000 | 3500 | 4000 | 5500 |

| 2 | Inner space between tie bars (H*V) | mm | 580×580 | 600×600 | 630×630 | 750×750 |

| 3 | Die Stroke | mm | 450 | 560 | 580 | 580 |

| 4 | Die Thickness | mm | 250~650 | 250~700 | 300~800 | 350~850 |

| 5 | Ejection Stroke | mm | 110 | 145 | 145 | 150 |

| 6 | Ejection Force | KN | 150 | 170 | 190 | 266 |

| 7 | Injeciton Force | KN | 133~300 | 150~360 | 160~400 | 200~520 |

| 8 | Injection position (center is "0",down is "-") | mm | 0,-160 | 0,-160 | 0,-175 | 0,-220 |

| 9 | Dia. of shot sleeve | mm | 50,60,70 | 60,70,80 | 60,70,80 | 70,80,90 |

| 10 | Dia.of Injection chamber flange | mm | 110f7 | 110f7 | 130 | 130f7 |

| 11 | Over height of flange | mm | 12-0.05 | 12-0.05 | 15-0.05 | 15-0.05 |

| 12 | Dosage of fluid metal pershot | kg | 3.2(Al.) 2.3(Mg.) | 4.2(Al.) 3.0(Mg.) | 5(Al.) | 6(Al). 4.3(Mg) |

| 13 | Projected area | cm | 196~800 | 275~1167 | 283~1258 | 407~1749 |

| 14 | Injection pressure | Mpa | 35~143 | 30~127 | 35~142 | 31.5~135 |

| 15 | Dry cycle | s | 10 | 10 | 10 | 13 |

| 16 | Oil tank capacity | L | 750 | 800 | 800 | 1100 |

| 17 | Motor power | KW | 18.5 | 22 | 22 | 30 |

| 18 | Machine sizes (L*W*H) | M | 6.4×1.6×2.8 | 6.8×1.7×2.8 | 7.5×1.9×3.0 | 8.0×2.0×3.8 |

(Remark:The company keeps the right to revise above parameters, If there is any alterations, advance notice won't be given then.)

| No. | ITEM | UNIT | LZ700 | LZ850 | LZ1100 | LZ1300 |

| 1 | Clamping Force | KN | 7000 | 8500 | 11000 | 13000 |

| 2 | Inner space between tie bars (H*V) | mm | 830×830 | 920×920 | 1030×1030 | 1100×1100 |

| 3 | Die Stroke | mm | 820 | 900 | 950 | 850 |

| 4 | Die Thickness | mm | 350~900 | 400~1000 | 450~1150 | 550~1200 |

| 5 | Ejection Stroke | mm | 200 | 240 | 190 | 200 |

| 6 | Ejection Force | KN | 316 | 400 | 500 | 570 |

| 7 | Injeciton Force | KN | 235~680 | 280~750 | 900 | 440~1100 |

| 8 | Injection position (center is "0",down is "-") | mm | 0,-250 | 0,-250 | 0,-150,-300 | 0,-320 |

| 9 | Dia. of shot sleeve | mm | 80,60,100 | 80,60,100, 110,120 | 90,100,110,120,130 | 100,110,120, 130,140 |

| 10 | Dia.of Injection chamber flange | mm | 165f7 | 180f7 | 240f7 | 130f7 |

| 11 | Over height of flange | mm | 15-0.05 | 20-0.05 | 20-0.05 | 25-0.05 |

| 12 | Dosage of fluid metal pershot | kg | 12.4(Al.) | 16(Al.) | 21.1(Al.) | 26(Al). |

| 13 | Projected area | cm | 518~972 | 570~3400 | 711~3166 | 928.6~4545 |

| 14 | Injection pressure | Mpa | 30~135.4 | 68~149 | 30~133.6 | 28.6~140 |

| 15 | Dry cycle | s | 13 | 14 | 14 | 19 |

| 16 | Oil tank capacity | L | 1200 | 1600 | 1600 | 2200 |

| 17 | Motor power | KW | 37 | 45 | 30*2 | 37*2 |

| 18 | Machine sizes (L*W*H) | M | 8.6×2×3.3 | 10.5×2.4×3.4 | 9.1×2.2×3.3 | 12×2.8×4.5 |

(Remark:The company keeps the right to revise above parameters, If there is any alterations, advance notice won't be given then.)

PDF TYPE:

LZ150~LZ2000  LZ150LZ2000 cold chabmer die casting machine specifications and parameters.pdf

LZ150LZ2000 cold chabmer die casting machine specifications and parameters.pdf

JPG TYPE:

LZ150~LZ550  LZ150LZ550 cold chabmer die casting machine specifications and parameters.jpg

LZ150LZ550 cold chabmer die casting machine specifications and parameters.jpg

LZ700~LZ2000  LZ700LZ2000 cold chabmer die casting machine specifications and parameters.jpg

LZ700LZ2000 cold chabmer die casting machine specifications and parameters.jpg

More die casting machine catalog, images, photos or die casting videos, pls. email us: cnkylt@aliyun.com

The information of die casting machine for sale and die casting machine price, pls. email us: cnkylt@aliyun.com

By providing customers with pre-sales services of investment budget, plant planning and other forms, customers' planningis reasonable, standardized and cost saving.

Investment budget die casting machine selection and auxiliary equipment matching and budget

Plant planning: provide installation size of equipment foundation, equipment layout, workshop ventilation, exhaust, watertransportation, wiring, lifting equipment design services.

Provide information of various casting auxiliary equipment.

Provide FREE standard spare parts together with machine.

Arrange engineers to your factory to install and adjust machines. Traning the worker to operate the machine.

Any questions be replied by email, video, photos within 24hr.

Our engineer can guide your operater to work and adjust machine by video on line.

Quality guarantee period: 12 months after machine put into operation.

If the equipment fails during the guarantee peirod, the manufacturer shall repair and replace accessories free of charge.

(Photo shows LZ 1100 cold chamber pressure casting machine with after sale service: assembly and running test.)

Used cold chamber die casting machines repairment (About used aluminum die casting machine price & cost for maintain, please contact with: cnkylt@aliyun.com )

Old high pressure die casting equipment improvement

(Used Toshiba die casting machine have a complete overhaul in our factory. Photo show the injection molding structure of a used Toshiba aluminum die caster. )

(You can found cold chamber die casting machine, aluminum die cast machine, die casting machine working process in our factory. Or visit our die casting machine clients.)

Choose The Perfect aluminium casting machine, please send us your aluminum project drawings or samples. Our engineer will choose suitable machine types and provide suggestions for your item. Our service Email:cnkylt@aliyun.com

Aluminum die casting machine widely used to produce cast aluminum parts for applications in various end-user sectors, such as Household Electric Appliances, Kitchen appliances, automotive, agriculture machinery etc.

High pressure aluminum alloy die casting machine accounted for about 70% of the aluminum die casting machinery market share.

Bühler, Toshiba, Dynacast, Oskar , Idra Group are the world famous top five aluminium die casting machinery manufacturers.

Normally there are 2kinds die casting machines: Horizontal type, Vertical type

Horizontal die casting machine has cold chamber and hot chamber version.

Aluminum pressure die casting machine is horizontal cold chamber type. For big scale and heavy weight zinc alloy die cast parts also use horizontal cold chamber die casting machine.

Horizontal hot chamber die casting machine is used to cast zinc, lead, tin alloy parts.

Vertical die casting machine most is to cast low melting point metal alloy, such as zinc, lead, tin alloys. The die cast parts features, which have insert parts to cast with alloy together. And Vertical die cast machine is easy for set insert parts in mold cavities.

LZ die-casting machinery is one Horizontal cold chamber pressure die casting machine manufacturer from china. We have 150T, 160T, 200T, 280T, 300T, 350T, 400T, 550T, 700T, 800T, 1100T. 1300T, 2000T for sale.

Cold chamber Die Casting Machines suitable for Aluminum alloy, Zinc alloy, Magnesium alloy, Copper alloy and Lead alloy casting. All those metal alloys be cast with high pressure. Molten metal be forced into mold cavities through cold chamber by plunger.

There are two kinds aluminum alloy die casting working process: Manual, Automatic.

Aluminum die casting machinery production line main consist two sections: horizontal cold chamber die-casting machine, aluminum melting furnace. With a die casting mould, the manual aluminum die casting process is established.

Video of manual die casting method:

Automatic aluminum die casting process consists: Aluminum melting furnace, Metal ladling machine, Aluminum die casting machine, Spraying machine, die casting parts pick-up machine.

Melting furnace heats by electric or gas, ladling machine ladles molten aluminum alloy from furnace to die casting machine cold chamber. Injection mechanism shot liquid aluminum alloy into mold cavities. Mold open, solid aluminum die cast parts be ejected out from mold cavities. Die casting parts pick-up machine take out the metal parts. Sprayer cools and lubricates the mold cavity.

Video of Aluminum automatic die casting working process:

https://www.youtube.com/shorts/npYbgva3NK8

Aluminum die casting machine price or cost depends on die casting manufacturers capital budget and demand. Small tonnage die casting machine and manual die casting process are cheap.

| No. | ITEM | UNIT | LZ150/160 | LZ180 | LZ200 | LZ268 |

| 1 | Clamping Force | KN | 1500/1600 | 1800 | 2000 | 2680 |

| 2 | Inner space between tie bars (H*V) | mm | 440×440 | 480×480 | 490×490 | 540×540 |

| 3 | Die Stroke | mm | 340 | 380 | 380 | 450 |

| 4 | Die Thickness | mm | 200~550 | 200~550 | 200~550 | 250~650 |

| 5 | Ejection Stroke | mm | 80 | 80 | 80 | 110 |

| 6 | Ejection Force | KN | 100 | 110 | 110 | 150 |

| 7 | Injeciton Force | KN | 110~190 | 105~230 | 105~236 | 133~280 |

| 8 | Injection position (center is "0",down is "-") | mm | 0,-70,-140 | 0,-140 | 0,-140 | 0,-160 |

| 9 | Dia. of shot sleeve | mm | 40,50,60 | 50,60,70 | 50,60,70 | 50,60,70 |

| 10 | Dia.of Injection chamber flange | mm | 110 | 110f7 | 110f7 | 110f7 |

| 11 | Over height of flange | mm | 10-0.05 | 10-0.05 | 10-0.05 | 12-0.05 |

| 12 | Dosage of fluid metal pershot | kg | 1.8 | 2.5 | 2.5 | 3.2(Al). 2.3(Mg) |

| 13 | Projected area | cm | 105~550 | 171~666 | 172~660 | 196~800 |

| 14 | Injection pressure | Mpa | 36~149 | 27.3~117 | 28~118 | 35~143 |

| 15 | Dry cycle | s | 7 | 7 | 7 | 10 |

| 16 | Oil tank capacity | L | 450 | 550 | 650 | 750 |

| 17 | Motor power | KW | 11 | 11 | 15 | 18.5 |

| 18 | Machine sizes (L*W*H) | M | 5.1×1.2×2.2 | 5.7×1.3×2.4 | 5.8×1.25×2.4 | 6.4×1.6×2.8 |

(Remark:The company keeps the right to revise above parameters, If there is any alterations, advance notice won't be given then.)

| No. | ITEM | UNIT | LZ300 | LZ350 | LZ400 | LZ550 |

| 1 | Clamping Force | KN | 3000 | 3500 | 4000 | 5500 |

| 2 | Inner space between tie bars (H*V) | mm | 580×580 | 600×600 | 630×630 | 750×750 |

| 3 | Die Stroke | mm | 450 | 560 | 580 | 580 |

| 4 | Die Thickness | mm | 250~650 | 250~700 | 300~800 | 350~850 |

| 5 | Ejection Stroke | mm | 110 | 145 | 145 | 150 |

| 6 | Ejection Force | KN | 150 | 170 | 190 | 266 |

| 7 | Injeciton Force | KN | 133~300 | 150~360 | 160~400 | 200~520 |

| 8 | Injection position (center is "0",down is "-") | mm | 0,-160 | 0,-160 | 0,-175 | 0,-220 |

| 9 | Dia. of shot sleeve | mm | 50,60,70 | 60,70,80 | 60,70,80 | 70,80,90 |

| 10 | Dia.of Injection chamber flange | mm | 110f7 | 110f7 | 130 | 130f7 |

| 11 | Over height of flange | mm | 12-0.05 | 12-0.05 | 15-0.05 | 15-0.05 |

| 12 | Dosage of fluid metal pershot | kg | 3.2(Al.) 2.3(Mg.) | 4.2(Al.) 3.0(Mg.) | 5(Al.) | 6(Al). 4.3(Mg) |

| 13 | Projected area | cm | 196~800 | 275~1167 | 283~1258 | 407~1749 |

| 14 | Injection pressure | Mpa | 35~143 | 30~127 | 35~142 | 31.5~135 |

| 15 | Dry cycle | s | 10 | 10 | 10 | 13 |

| 16 | Oil tank capacity | L | 750 | 800 | 800 | 1100 |

| 17 | Motor power | KW | 18.5 | 22 | 22 | 30 |

| 18 | Machine sizes (L*W*H) | M | 6.4×1.6×2.8 | 6.8×1.7×2.8 | 7.5×1.9×3.0 | 8.0×2.0×3.8 |

(Remark:The company keeps the right to revise above parameters, If there is any alterations, advance notice won't be given then.)

| No. | ITEM | UNIT | LZ700 | LZ850 | LZ1100 | LZ1300 |

| 1 | Clamping Force | KN | 7000 | 8500 | 11000 | 13000 |

| 2 | Inner space between tie bars (H*V) | mm | 830×830 | 920×920 | 1030×1030 | 1100×1100 |

| 3 | Die Stroke | mm | 820 | 900 | 950 | 850 |

| 4 | Die Thickness | mm | 350~900 | 400~1000 | 450~1150 | 550~1200 |

| 5 | Ejection Stroke | mm | 200 | 240 | 190 | 200 |

| 6 | Ejection Force | KN | 316 | 400 | 500 | 570 |

| 7 | Injeciton Force | KN | 235~680 | 280~750 | 900 | 440~1100 |

| 8 | Injection position (center is "0",down is "-") | mm | 0,-250 | 0,-250 | 0,-150,-300 | 0,-320 |

| 9 | Dia. of shot sleeve | mm | 80,60,100 | 80,60,100, 110,120 | 90,100,110,120,130 | 100,110,120, 130,140 |

| 10 | Dia.of Injection chamber flange | mm | 165f7 | 180f7 | 240f7 | 130f7 |

| 11 | Over height of flange | mm | 15-0.05 | 20-0.05 | 20-0.05 | 25-0.05 |

| 12 | Dosage of fluid metal pershot | kg | 12.4(Al.) | 16(Al.) | 21.1(Al.) | 26(Al). |

| 13 | Projected area | cm | 518~972 | 570~3400 | 711~3166 | 928.6~4545 |

| 14 | Injection pressure | Mpa | 30~135.4 | 68~149 | 30~133.6 | 28.6~140 |

| 15 | Dry cycle | s | 13 | 14 | 14 | 19 |

| 16 | Oil tank capacity | L | 1200 | 1600 | 1600 | 2200 |

| 17 | Motor power | KW | 37 | 45 | 30*2 | 37*2 |

| 18 | Machine sizes (L*W*H) | M | 8.6×2×3.3 | 10.5×2.4×3.4 | 9.1×2.2×3.3 | 12×2.8×4.5 |

(Remark:The company keeps the right to revise above parameters, If there is any alterations, advance notice won't be given then.)

PDF TYPE:

LZ150~LZ2000  LZ150LZ2000 cold chabmer die casting machine specifications and parameters.pdf

LZ150LZ2000 cold chabmer die casting machine specifications and parameters.pdf

JPG TYPE:

LZ150~LZ550  LZ150LZ550 cold chabmer die casting machine specifications and parameters.jpg

LZ150LZ550 cold chabmer die casting machine specifications and parameters.jpg

LZ700~LZ2000  LZ700LZ2000 cold chabmer die casting machine specifications and parameters.jpg

LZ700LZ2000 cold chabmer die casting machine specifications and parameters.jpg

More die casting machine catalog, images, photos or die casting videos, pls. email us: cnkylt@aliyun.com

The information of die casting machine for sale and die casting machine price, pls. email us: cnkylt@aliyun.com

By providing customers with pre-sales services of investment budget, plant planning and other forms, customers' planningis reasonable, standardized and cost saving.

Investment budget die casting machine selection and auxiliary equipment matching and budget

Plant planning: provide installation size of equipment foundation, equipment layout, workshop ventilation, exhaust, watertransportation, wiring, lifting equipment design services.

Provide information of various casting auxiliary equipment.

Provide FREE standard spare parts together with machine.

Arrange engineers to your factory to install and adjust machines. Traning the worker to operate the machine.

Any questions be replied by email, video, photos within 24hr.

Our engineer can guide your operater to work and adjust machine by video on line.

Quality guarantee period: 12 months after machine put into operation.

If the equipment fails during the guarantee peirod, the manufacturer shall repair and replace accessories free of charge.

(Photo shows LZ 1100 cold chamber pressure casting machine with after sale service: assembly and running test.)

Used cold chamber die casting machines repairment (About used aluminum die casting machine price & cost for maintain, please contact with: cnkylt@aliyun.com )

Old high pressure die casting equipment improvement

(Used Toshiba die casting machine have a complete overhaul in our factory. Photo show the injection molding structure of a used Toshiba aluminum die caster. )

(You can found cold chamber die casting machine, aluminum die cast machine, die casting machine working process in our factory. Or visit our die casting machine clients.)

Choose The Perfect aluminium casting machine, please send us your aluminum project drawings or samples. Our engineer will choose suitable machine types and provide suggestions for your item. Our service Email:cnkylt@aliyun.com