Services Email: cnkylt@aliyun.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Manufacturing on Demand, from Die Casting to Machining, from Molds making to Injection molding

KYLT has a complete solution for custom product manufacturing, from finished Metal parts & Plastic parts production to Assembly as per end users' demands. We provide “ONE-STOP” services with Good Quality, Competitive Prices, and Fast Delivery.

Quality Products

Quality Products

Safe & Custom Packing

Safe & Custom Packing

Get fresh ideas to improve your business by reading our latest blogs and cases.

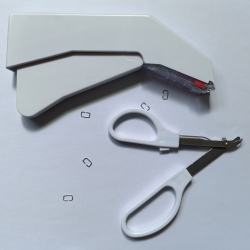

Auto skin stapler nails feeding machine is a key equipment in the production of skin staplers.Skin stapler nails automatic feeding machine is a specially designed machine used to automatically feed stapler nails into a nail box. The automatic feeding machine for skin stapler nails organizes and supplies stapler nails into the nail compartment box. This innovation significantly enhances the filling efficiency and quality skin staplers.

Where to buy a complete set of parts to assemble disposable skin staplers? What are the specific parts in the complete set? How to assemble these parts? If you are a medical device purchaser or manufacturer, you would like to purchase a complete set of standard disposable skin suture accessories that are commonly used in the market at the most favorable price, without the need to invest in molds and have your brand. Please contact us: cnkylt@aliyun.com

Through Questions and Answers, learn more about Die casting, CNC machining / CNC milling / CNC turning, Plastic Moulding, and Die-casting machines.