Services Email: cnkylt@aliyun.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 71 Author: Site Editor Publish Time: 2024-04-19 Origin: Site

“Disposable skin suturing molds and accessories, direct sales from the manufacturer, the same accessories as medical device manufacturers, reliable and cost-effective.”

Disposable skin staplers are essential tools in the medical field, particularly in surgeries and wound closures. These devices simplify the process of closing wounds quickly and efficiently, reducing procedure times and minimizing patient discomfort.

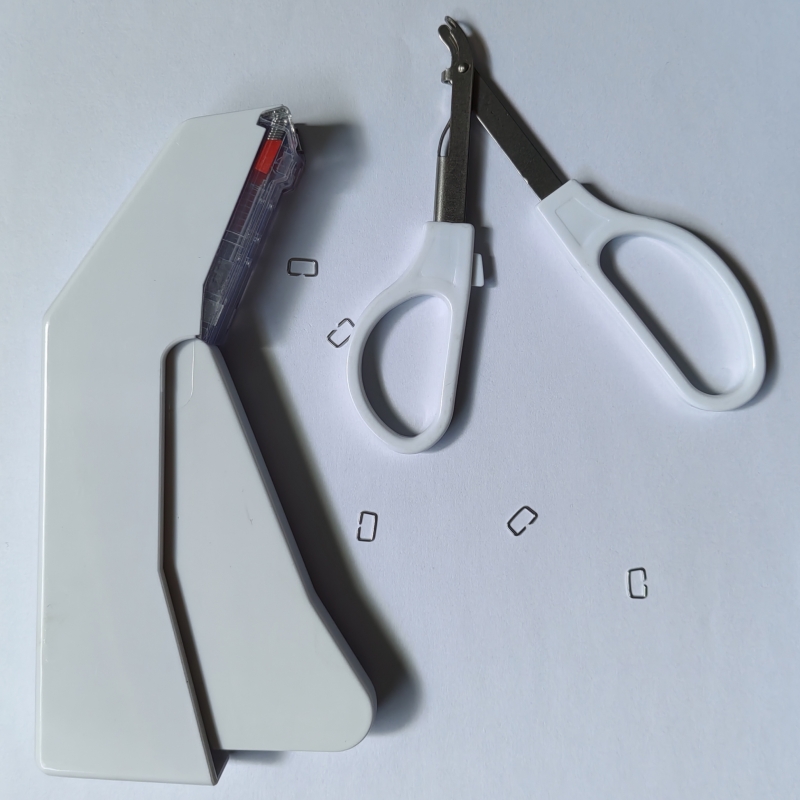

Firstly, we need to address three issues regarding the procurement and production of disposable skin stapler parts: where to buy a complete set of parts? What are the specific parts in the complete set? How to assemble these parts?

We are the source factory of metal parts and injection molded parts for disposable skin sutures, with over 15 years of experience in providing molds and injection molding production for medical device manufacturers. We provide free samples for customers to assemble and test, and request samples: cnkylt@aliyun.com

The complete set of disposable shell skin staplers consists of ten parts: Plastic Shell - 1pcs; Plastic Firing handle - 1pcs; Plastic staples pushing plate - 1pcs; Plastic suture staple base - 1pcs; Spring - 1pcs; Spring plate - 1pcs; Suture nail base - 1pcs; Staples (nail) -35pcs. Of course, if you need skin staples remover, also please me know.

The disposable surgIcal skin stapler assembly method and working process, please refer to the following video for installation steps: (The video is for trial installation reference only.)

Disposable skin stapler spare parts are the components necessary for the upkeep and repair of skin staplers. These parts include staple cartridges, staple housing assemblies, safety lock mechanisms, trigger mechanisms, and other essential components.

Now, our factory provide full set of plastic and metal parts for disposable skin staple (if clients need molds, we can make molds as per customers' design or samples).

After receiving the accessories, customers can assemble their own skin sutures, disinfect and sterilize them according to the domestic medical device production requirements, use their own brand and packaging, and then sell them on the market. So as to save mold costs, eliminate middlemen's price differences, and establish your own independent brands.

Get a CHEAP and FREE quote for your skin stapler & remover, pls. email us: cnkylt@aliyun.com

Using genuine spare parts is crucial for maintaining the effectiveness and safety of disposable skin staplers. Genuine parts are designed to meet the specific requirements and quality standards of the original equipment manufacturer (OEM), ensuring compatibility and optimal performance.

This disposable surgical skin stapler comes with 35 staples. We will randomly select each component for assembly and check if the quality of each component is stable, in order to ensure that the quality of the accessories received by customers is excellent.

Disposable skin staplers consist of several key components, each playing a vital role in the stapling process. Our disposable skin stapler consists of 10 pieces spare parts, detail as follows:

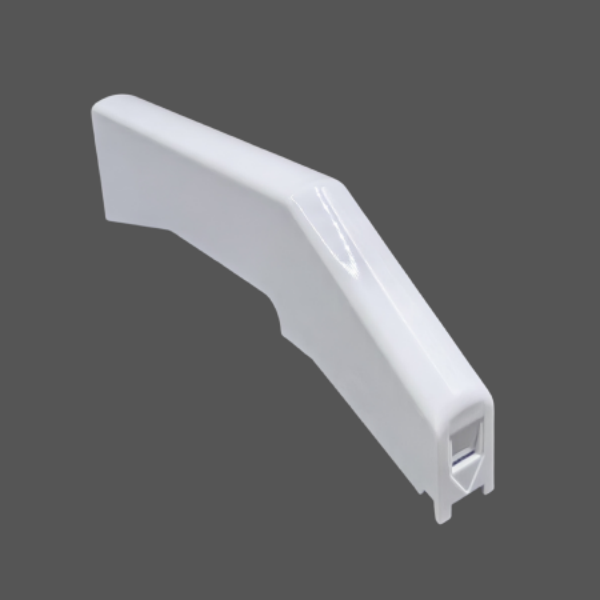

Shell

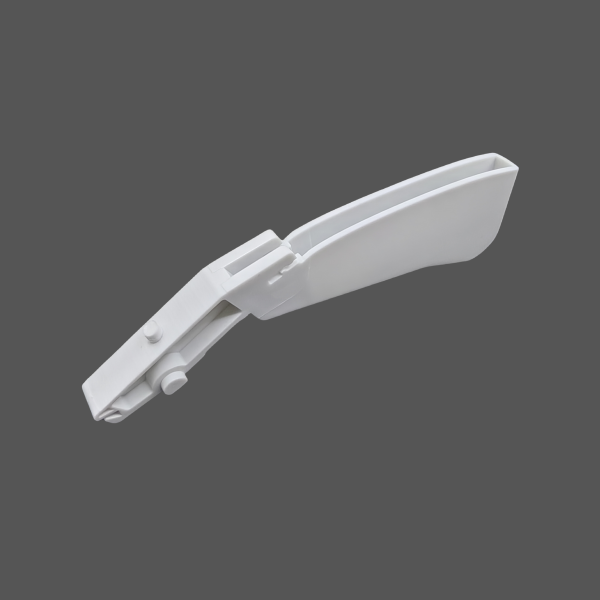

Firing handle

Nail pushing plate

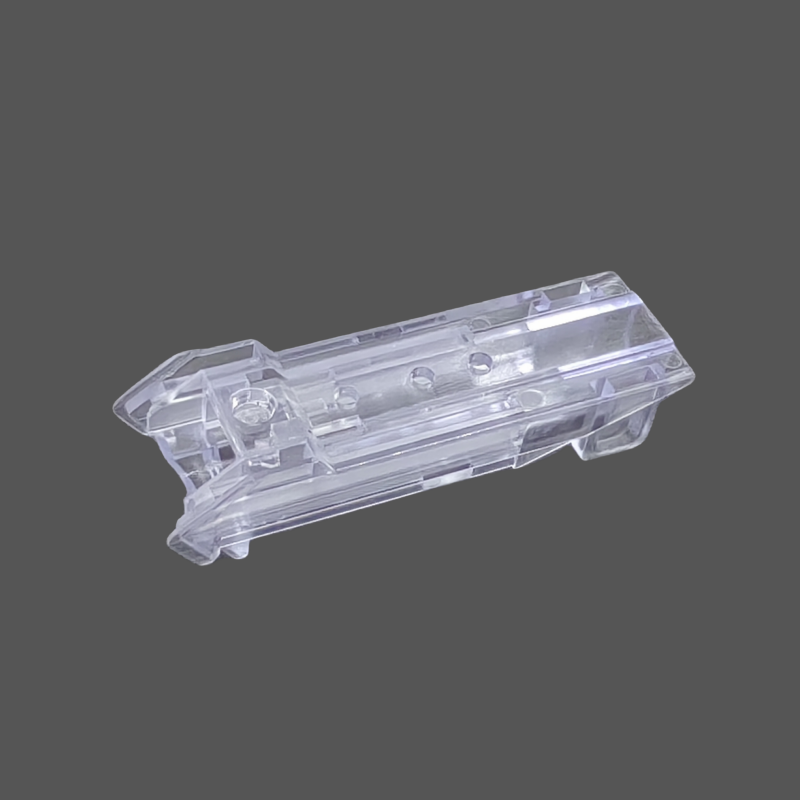

Suture nail box(Staples box)

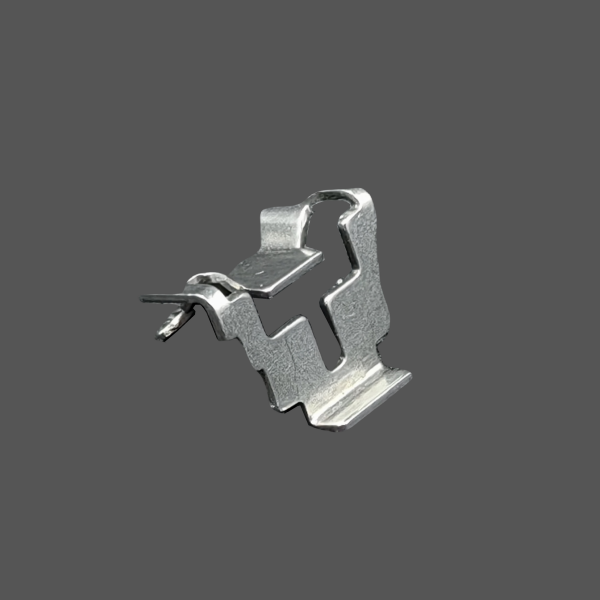

Staples forming part

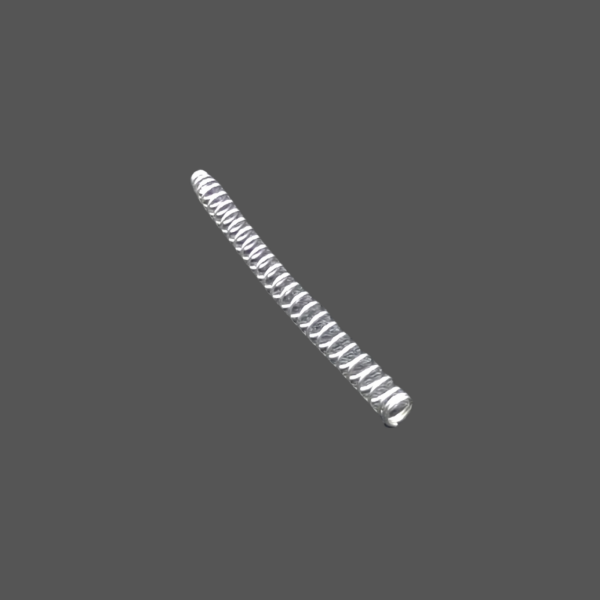

Spring

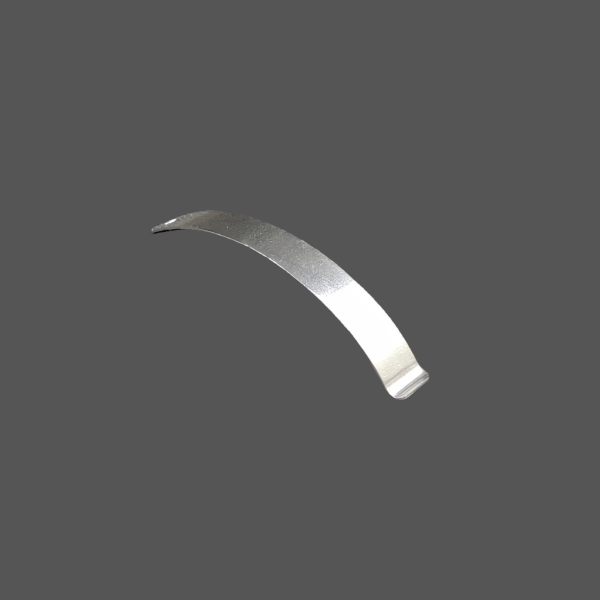

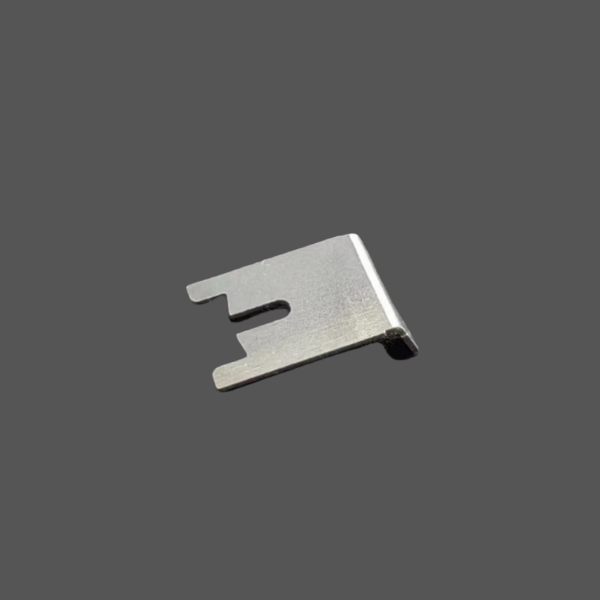

Spring plate

Suture nail base

Staples (suturing nail)

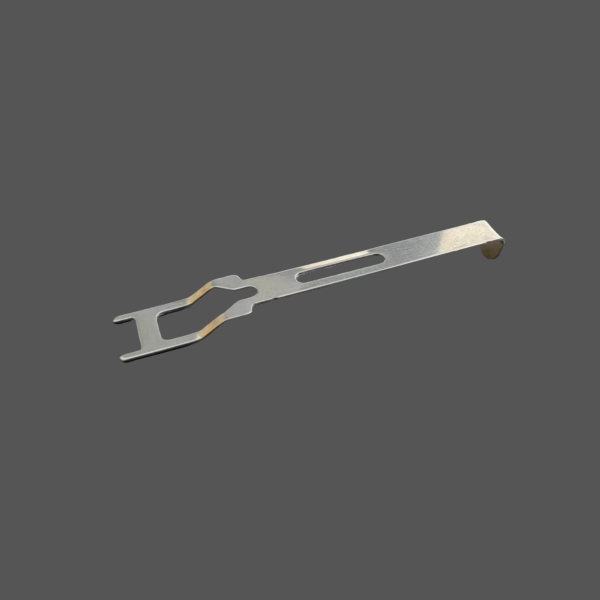

Nail (staple) pressing plate

| SHELL | ABS | As the handle of the entire skin stapler, it provides structure and installation space for the assembly of various parts. |

| FIRING HANDLE | ABS | As a trigger mechanism, it controls the firing of the staples, allowing precise placement and tension adjustment. |

| NAIL PUSHING PLATE | ABS | After each sewing action is triggered, the staples pushing plate will push the next staples into and maintain it within the working range. |

| SUTURE NAIL BOX | PC | Worked as the function of staples cartridge & housing, to hold and house the staples cartridge and provide support and alignment for the staples during deployment. |

| STAPLES FORMING PART | STAINLESS STEEL | Used for bending and sewing, achieving the function of skin wound suturing. |

| SPRING | STAINLESS STEEL | Used to push the nail pushing plate, thereby pushing the saples forward. |

| SPRING PLATE | STAINLESS STEEL | Used to control the rebound of the firing handle. |

| SUTURE NAIL BASE | STAINLESS STEEL | After the suture staple is formed, separate it from the skin stapler. |

| STAPLES | STAINLESS STEEL | Used for suturing wounds. Each skin stapler comes with 35 staples. |

| NAIL PRESSING PLATE | STAINLESS STEEL | Working together with the staples to form metal parts, pressing and bending the staples to sew the wound. |

As the key assembling machine, Skin stapler nails automatic feeding machine is a specially designed machine used to automatically feed stapler nails into a nail box. The automatic feeding machine for skin stapler nails organizes and supplies stapler nails into the nail compartment box. This innovation significantly enhances the filling efficiency and quality skin staplers.

More information on the Skin stapler nails automatic feeding machine, please click the above photo or visit the YouTube video:

| Grade | 316L(022Cr17Ni12Mo2) | Sort | B-SPR | Heat No. | NY220303AW04 |

| Dia.(mm) | 0.59 | TS(MPa) | 925 | Surface condition | GOOD |

| Chemical Composition(%) | |||||

| C | 0.016 | Si | 0.35 | Mn | 0.95 |

| P | 0.025 | S | 0.001 | Cr | 17.66 |

| Ni | 12.05 | Mo | 2.26 | Cu | 0.32 |

| N | 0.026 | ||||

| Product form | SUS | Thickness*Width*Length | 0.5*65*C | Type | 304 |

| Temper | 3/4 | Standard | JIS G430-2021 | ||

| Chemical Composition(%) | |||||

| C | 0.0346 | Si | 0.486 | Mn | 1.094 |

| P | 0.0316 | S | 0.0018 | Cr | 18.126 |

| Ni | 8.023 | ||||

| Mechanical Properties | |||||

| T.S(N/mm2) | 1290 | Y.S(0.2%)(N/mm2) | 1050 | Elong(%) | 12 |

| Hardness (HV) | 330 | ||||

This surgical skin stapler is disposable and does not require daily maintenance.

As the source factory of medical device accessories, we have 15 years of experience in medical product mold making and injection molding. We provide year-round accessory production and product development services to various medical device manufacturers. All parts of this skin stapler are factory sourced accessories, and are the same type of accessory for various medical device manufacturers.

We can provide free samples and offer the best factory prices. Please contact us for sample requests: cnkylt@aliyun.com

A1. A skin stapler is used for closing wounds during surgery or in emergency medical situations.

A2. Staples are often used instead of stitches for their speed and ease of application, particularly in areas with high tension or where precise alignment is difficult.

A3. Skin staplers can be disposable or reusable, depending on the type and manufacturer.

A4. Stapling a wound can be effective for closing it quickly and securely, but it's important to ensure proper technique and follow-up care to prevent complications.

A5. This typically includes shell, firing handle, nail pushing plate, suture nail box, staplers forming part, spring, spring plate, suture nail base, staples, nail pressing plate.

A6. Yes, customized molds can be designed and manufactured to meet specific client requirements and device specifications. Just send your skin stapler samples or drawing to us, we will quote for them immediately. Service Email: cnkylt@aliyun.com

A7. Molds are usually made from high-grade steel for durability, while spare parts are made of medical-grade materials such as stainless steel and biocompatible plastics.

A8. Lead times vary depending on order size and customization but generally range from 8 to 12 weeks.

A9. Most suppliers offer technical documentation, video tutorials, and customer support to assist with part installation and maintenance.