Services Email: cnkylt@aliyun.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Material: | |

|---|---|

| Size: | |

| Mold service: | |

| Usage: | |

| Working period: | |

| Availability: | |

150-1100T

LZ

HS:8454301000

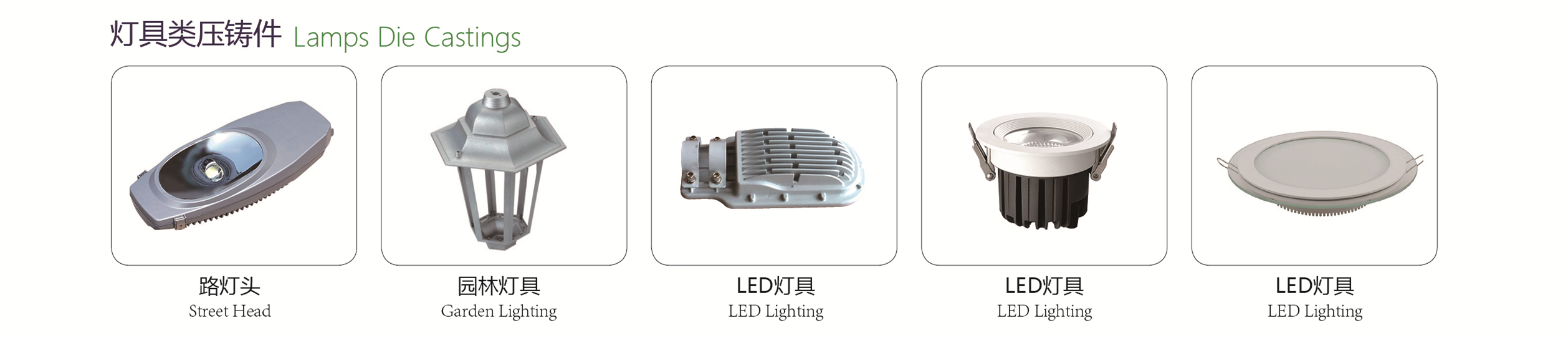

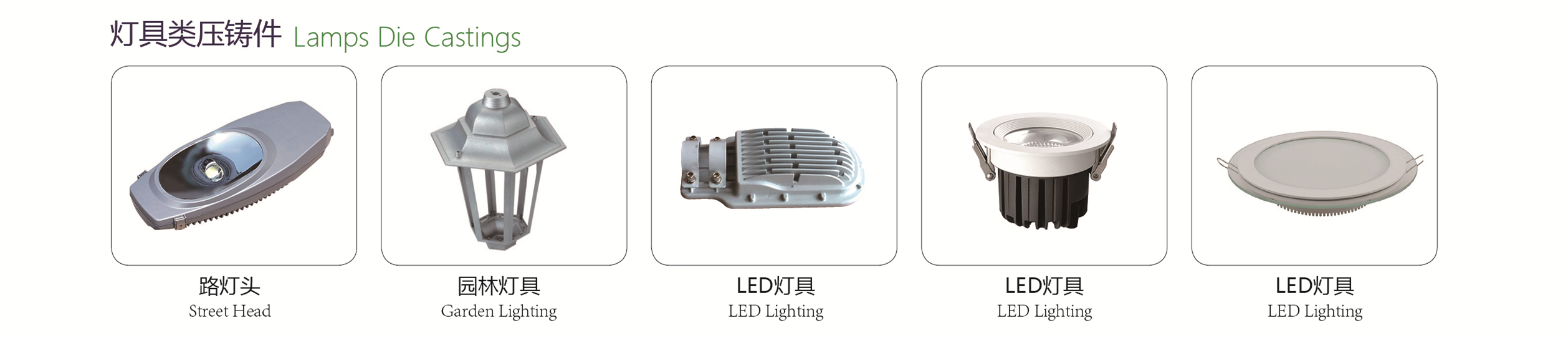

Lamp Light Parts Die Casting Machine, that is Aluminum/Zinc Cold Chamber Die Casting Machine used to produce all kinds of lamps and spare parts. Such as: Wall lamp, post/street lamp, pillar lamp, bollard lamp, Courtyard lamp, Floor lamp, Landscape lamp, lamps and lanterns etc. Many lamps & parts are made by aluminum die casting.

Lamp holder, lamp shade, Lamp housing, lamp shell, lamp cover, LED heatsink, LED light base etc.

Zinc/Zmak die casting lamp/light parts most used in desk lamp. The base of table lamp or reading lamp are made Zinc/Zamak alloy. Zinc alloy is heavy, it works as a weight part to keep the desk lamp stable. Of course, outdoor Lamp holder etc parts also can be made from zinc/zamak alloy depends on design.

Aluminum die casting Lamps and parts have advantages:

1. Aluminum is strong, die cast lamp not damaged and deformed in transport process.

2. Aluminum Lamps are lightweight

3. Aluminum Lights/Lamps parts material cost is low

4. Aluminum die casting process is mature technology, mass production is easily, so the production cost is low, and die cast lamp part is cheap.

5. Aluminum is more sensitive to heat, it can cool down fastly. That is the reason use aluminum alloy to make LED heatsink

6. With die casting mold, aluminum can be cast to different shapes as per design. We can produce different shapes lamps. And produce complex structures parts for lamps.

7. Aluminum is good for machining, easy for assembling.

8. Many kinds of surface treatment can be done on aluminum die cast lamp parts surface. Painting, Powder coating, Plating etc is allowed.

150-300T Horizontal Cold Chamber Pressure Die Casting Machines can be used to small aluminum lamp holder, shade, cover, housing, LED heat sink,and other lamp parts.

Zinc/Zamak table lamp base normally use 200T cold chamber die casting machine is enough.

500-1300T Horizontal Cold Chamber Pressure Die Casting Machines used to produce big scale aluminum lamp parts. Such as street light housing, street lamp cover etc.

More information and price of Lamp Light Parts Die Casting Machine, Mould or Production line, please contact us: cnkylt@aliyun.com

Lamp Light Parts Die Casting Machine, that is Aluminum/Zinc Cold Chamber Die Casting Machine used to produce all kinds of lamps and spare parts. Such as: Wall lamp, post/street lamp, pillar lamp, bollard lamp, Courtyard lamp, Floor lamp, Landscape lamp, lamps and lanterns etc. Many lamps & parts are made by aluminum die casting.

Lamp holder, lamp shade, Lamp housing, lamp shell, lamp cover, LED heatsink, LED light base etc.

Zinc/Zmak die casting lamp/light parts most used in desk lamp. The base of table lamp or reading lamp are made Zinc/Zamak alloy. Zinc alloy is heavy, it works as a weight part to keep the desk lamp stable. Of course, outdoor Lamp holder etc parts also can be made from zinc/zamak alloy depends on design.

Aluminum die casting Lamps and parts have advantages:

1. Aluminum is strong, die cast lamp not damaged and deformed in transport process.

2. Aluminum Lamps are lightweight

3. Aluminum Lights/Lamps parts material cost is low

4. Aluminum die casting process is mature technology, mass production is easily, so the production cost is low, and die cast lamp part is cheap.

5. Aluminum is more sensitive to heat, it can cool down fastly. That is the reason use aluminum alloy to make LED heatsink

6. With die casting mold, aluminum can be cast to different shapes as per design. We can produce different shapes lamps. And produce complex structures parts for lamps.

7. Aluminum is good for machining, easy for assembling.

8. Many kinds of surface treatment can be done on aluminum die cast lamp parts surface. Painting, Powder coating, Plating etc is allowed.

150-300T Horizontal Cold Chamber Pressure Die Casting Machines can be used to small aluminum lamp holder, shade, cover, housing, LED heat sink,and other lamp parts.

Zinc/Zamak table lamp base normally use 200T cold chamber die casting machine is enough.

500-1300T Horizontal Cold Chamber Pressure Die Casting Machines used to produce big scale aluminum lamp parts. Such as street light housing, street lamp cover etc.

More information and price of Lamp Light Parts Die Casting Machine, Mould or Production line, please contact us: cnkylt@aliyun.com