Services Email: cnkylt@aliyun.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Tonnage: | |

|---|---|

| Type: | |

| Size: | |

| Usage: | |

| Original: | |

| Shipping Port: | |

| Lead time: | |

| Availability: | |

3500KN

LZ

8454301000

| No. | ITEM | UNIT | LZ350 |

| 1 | Clamping Force | KN | 3500 |

| 2 | Inner space between tie bars(H*V) | mm | 600×600 |

| 3 | Die Stroke | mm | 560 |

| 4 | Die Thickness | mm | 250~700 |

| 5 | Ejection Stroke | mm | 145 |

| 6 | Ejection Force | KN | 170 |

| 7 | Injeciton Force | KN | 150~360 |

| 8 | Injection position(center is "0",down is "-") | mm | 0,-160 |

| 9 | Dia. of shot sleeve | mm | 60,70,80 |

| 10 | Dia.of Injection chamber flange | mm | 110f7 |

| 11 | Over height of flange | mm | 12-0.05 |

| 12 | Dosage of fluid metal pershot | kg | 4.2(Al.) 3.0(Mg.) |

| 13 | Projected area | cm | 275~1167 |

| 14 | Injection pressure | Mpa | 30~127 |

| 15 | Dry cycle | s | 10 |

| 16 | Oil tank capacity | L | 800 |

| 17 | Motor power | KW | 22 |

| 18 | Machine sizes(L*W*H) | M | 6.8×1.7×2.8 |

(Remark: 1.The die casting machine manufacturer keeps the right to revise above parameters, If there is any alterations, advance notice won't be given then. 2. Servo die casting machine can be choosed to save energy and cost. )

350T die casting machine image

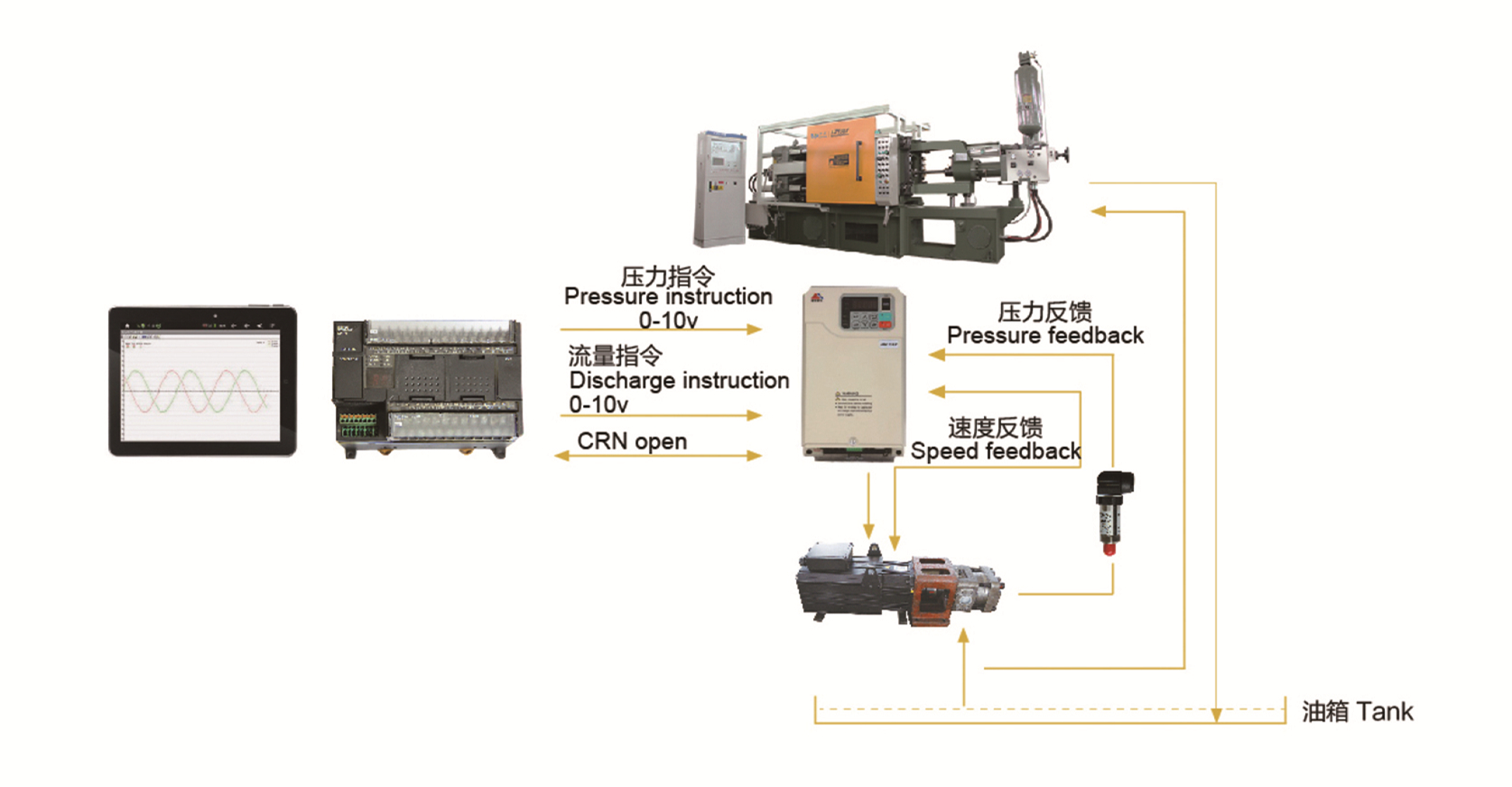

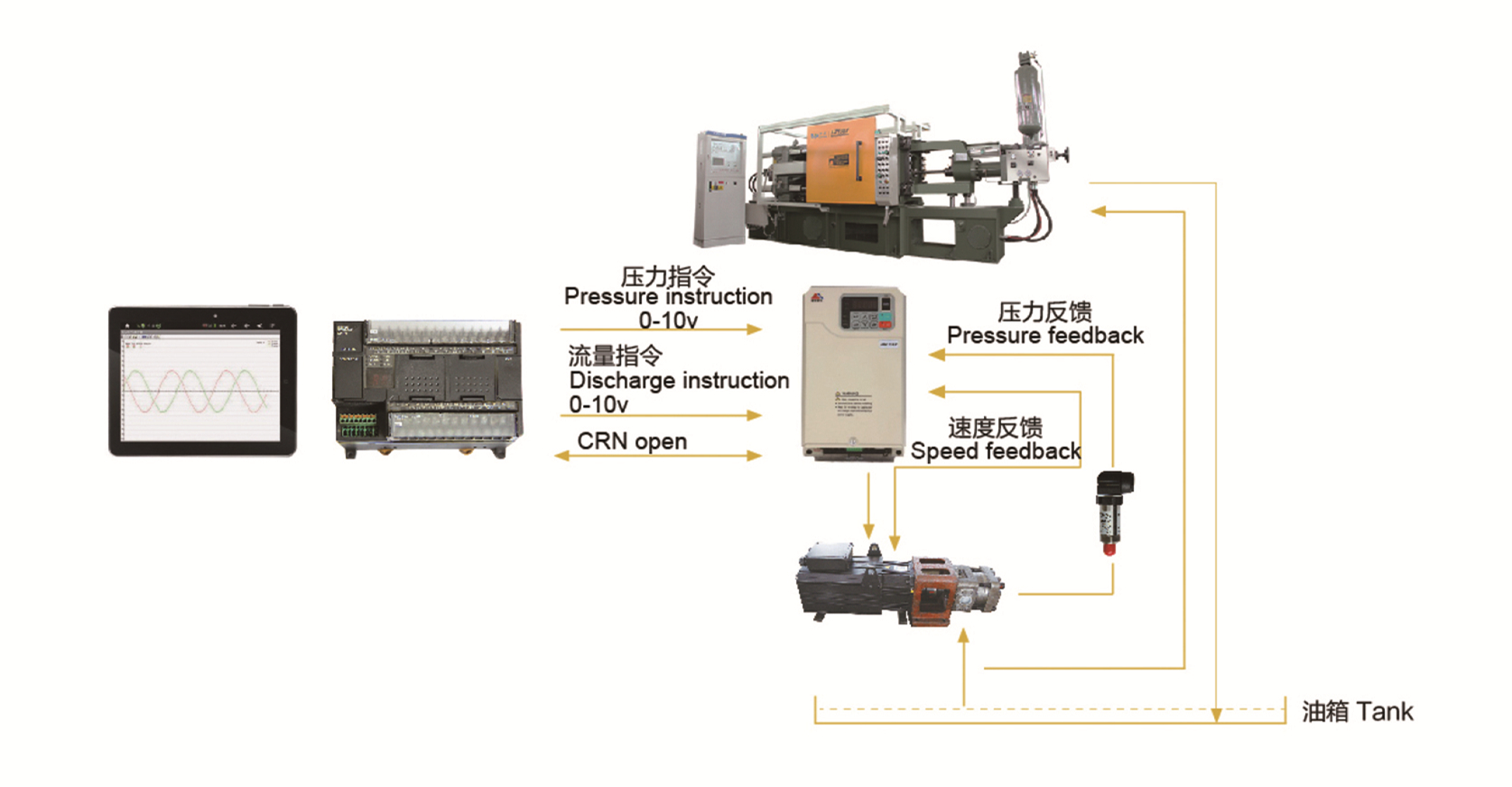

Servo driven system is an advisable choice for die casting machine factory. It features:

Energy saving

Rapid response and improved efficiency

Stable pressure and precision

High repetition accuracy

High speed and large lifting flow

Connection mode to improve heat dissipation performance

More information about 3500KN Cold Chamber Die Cast Machine Service, Please email us: cnkylt@aliyun.com

| No. | ITEM | UNIT | LZ350 |

| 1 | Clamping Force | KN | 3500 |

| 2 | Inner space between tie bars(H*V) | mm | 600×600 |

| 3 | Die Stroke | mm | 560 |

| 4 | Die Thickness | mm | 250~700 |

| 5 | Ejection Stroke | mm | 145 |

| 6 | Ejection Force | KN | 170 |

| 7 | Injeciton Force | KN | 150~360 |

| 8 | Injection position(center is "0",down is "-") | mm | 0,-160 |

| 9 | Dia. of shot sleeve | mm | 60,70,80 |

| 10 | Dia.of Injection chamber flange | mm | 110f7 |

| 11 | Over height of flange | mm | 12-0.05 |

| 12 | Dosage of fluid metal pershot | kg | 4.2(Al.) 3.0(Mg.) |

| 13 | Projected area | cm | 275~1167 |

| 14 | Injection pressure | Mpa | 30~127 |

| 15 | Dry cycle | s | 10 |

| 16 | Oil tank capacity | L | 800 |

| 17 | Motor power | KW | 22 |

| 18 | Machine sizes(L*W*H) | M | 6.8×1.7×2.8 |

(Remark: 1.The die casting machine manufacturer keeps the right to revise above parameters, If there is any alterations, advance notice won't be given then. 2. Servo die casting machine can be choosed to save energy and cost. )

350T die casting machine image

Servo driven system is an advisable choice for die casting machine factory. It features:

Energy saving

Rapid response and improved efficiency

Stable pressure and precision

High repetition accuracy

High speed and large lifting flow

Connection mode to improve heat dissipation performance

More information about 3500KN Cold Chamber Die Cast Machine Service, Please email us: cnkylt@aliyun.com