Services Email: cnkylt@aliyun.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Tonnage: | |

|---|---|

| Type: | |

| Size: | |

| Usage: | |

| Original: | |

| Shipping Port: | |

| Lead time: | |

| Availability: | |

400 TON

LZ

8454301000

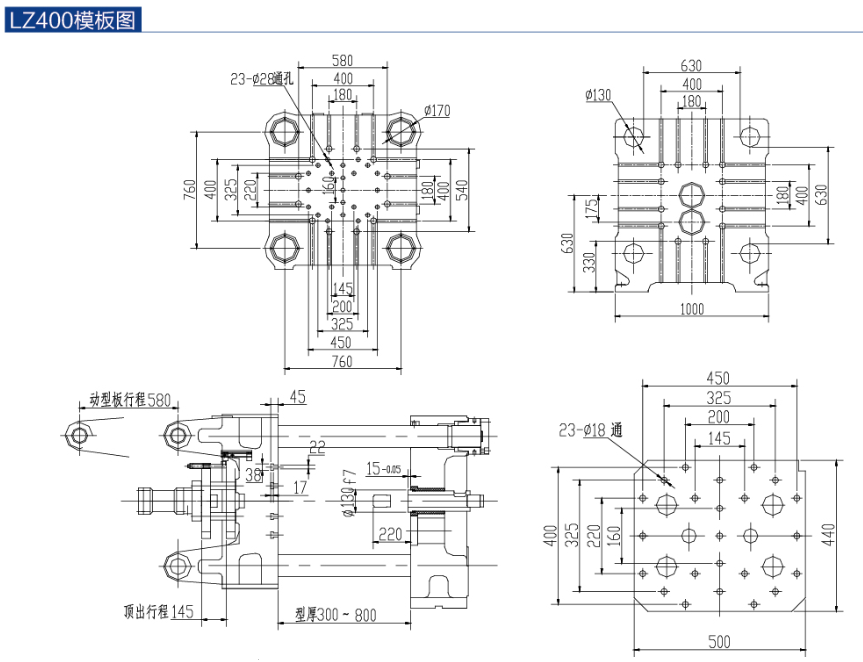

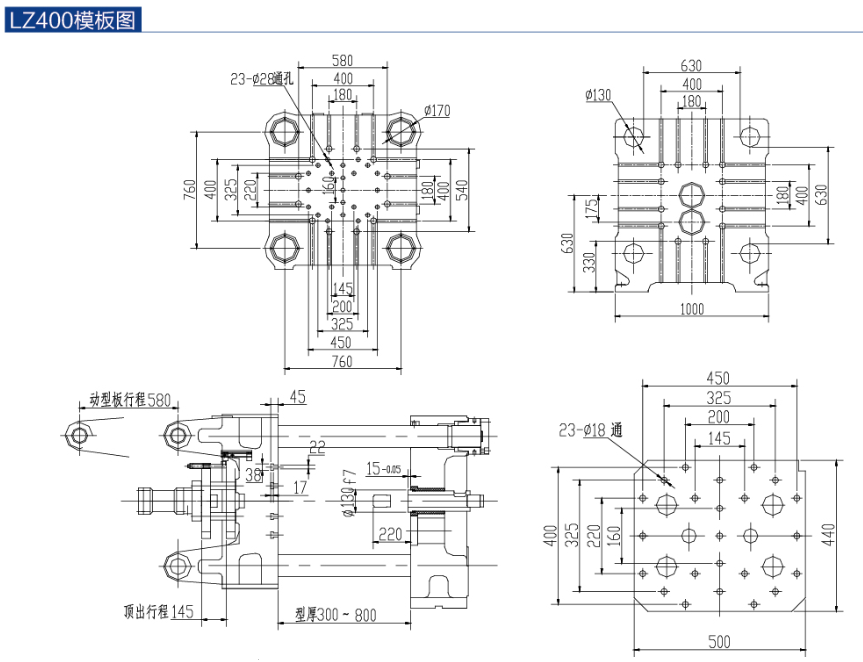

| No. | ITEM | UNIT | LZ400 |

| 1 | Clamping Force | KN | 4000 |

| 2 | Inner space between tie bars(H*V) | mm | 630×630 |

| 3 | Die Stroke | mm | 580 |

| 4 | Die Thickness | mm | 300~800 |

| 5 | Ejection Stroke | mm | 145 |

| 6 | Ejection Force | KN | 190 |

| 7 | Injeciton Force | KN | 160~400 |

| 8 | Injection position(center is "0",down is "-") | mm | 0,-175 |

| 9 | Dia. of shot sleeve | mm | 60,70,80 |

| 10 | Dia.of Injection chamber flange | mm | 130 |

| 11 | Over height of flange | mm | 15-0.05 |

| 12 | Dosage of fluid metal pershot | kg | 5(Al.) |

| 13 | Projected area | cm | 283~1258 |

| 14 | Injection pressure | Mpa | 35~142 |

| 15 | Dry cycle | s | 10 |

| 16 | Oil tank capacity | L | 800 |

| 17 | Motor power | KW | 22 |

| 18 | Machine sizes(L*W*H) | M | 7.5×1.9×3.0 |

(Remark: 1.The die casting machine supplier keeps the right to revise above parameters, If there is any alterations, advance notice won't be given then. 2. Servo die casting machine can be choosed to save energy and cost. )

Die casting machine operator ladles the liquid Aluminum/Zinc/Copper alloy out from furnace, pure it into pressure casting chamber. Cold chamber die casting machine plunger inject the liquid metal alloy to pressure die with high pressure. Metal alloy solid, die open, the die casting parts be ejected out from mould cavities. A die casting injection process is finished, sprayer lubricates and cools the die cavites, mould close, and ready to start the next pressure die casting cycle.

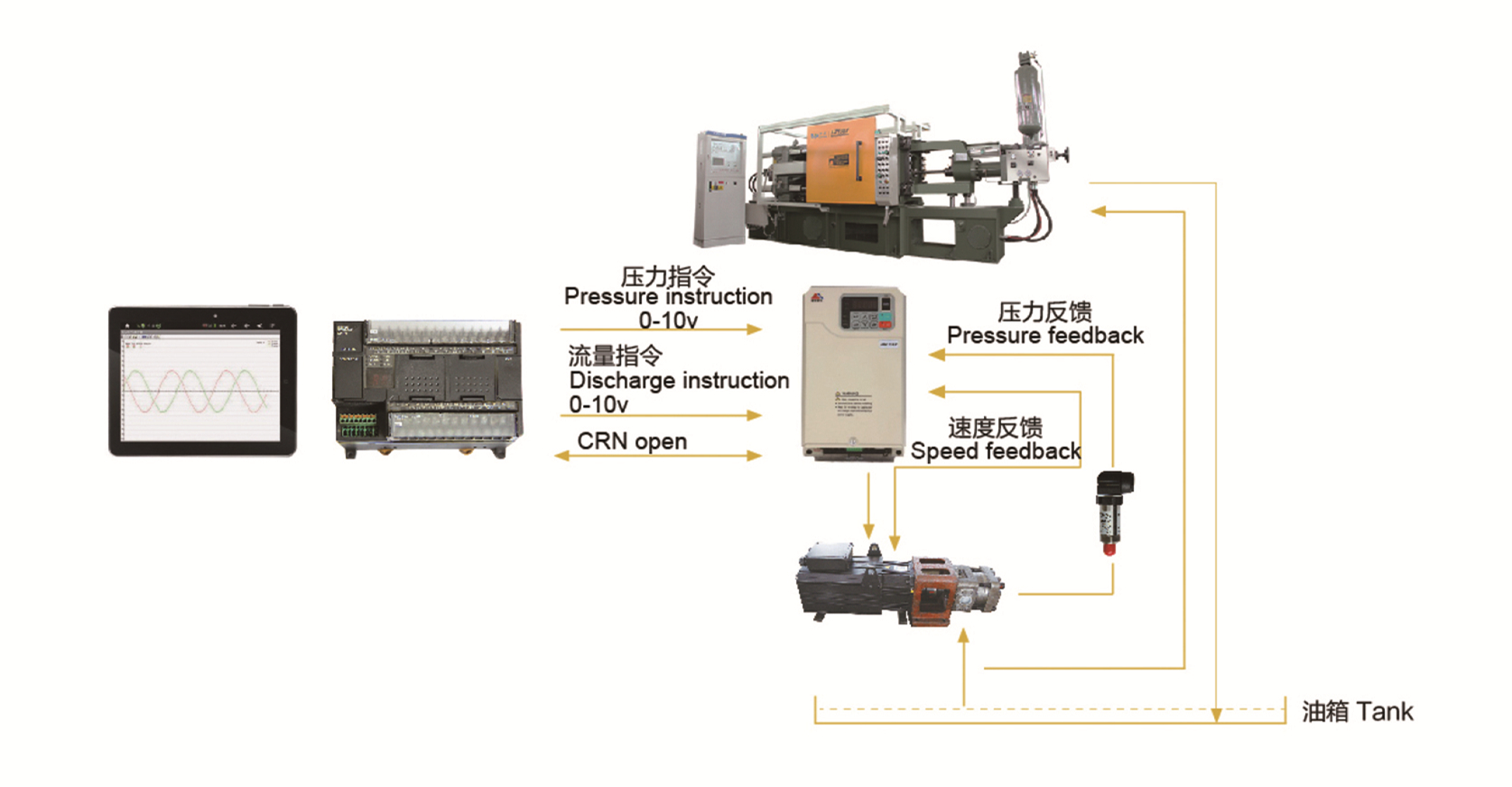

Servo driven system is an advisable choice for die casting machine factory. It features:

Energy saving

Rapid response and improved efficiency

Stable pressure and precision

High repetition accuracy

High speed and large lifting flow

Connection mode to improve heat dissipation performance

Auxiliary machines used to save labor or reach automatic die cast process.

Aluminum alloy melting furnace

Automatic ladling machine

Spraying Machine

Auto part off machine (Die casting parts pick-up machine / Extractor)

Technical information and prices of 400Ton PLC Horizontal High Pressure Die Cast Machine, Automatic ladling machine, Auto Spraying machine, Auto die cast parts pick-up machine and melting furnace, Please email: cnkylt@aliyun.com

| No. | ITEM | UNIT | LZ400 |

| 1 | Clamping Force | KN | 4000 |

| 2 | Inner space between tie bars(H*V) | mm | 630×630 |

| 3 | Die Stroke | mm | 580 |

| 4 | Die Thickness | mm | 300~800 |

| 5 | Ejection Stroke | mm | 145 |

| 6 | Ejection Force | KN | 190 |

| 7 | Injeciton Force | KN | 160~400 |

| 8 | Injection position(center is "0",down is "-") | mm | 0,-175 |

| 9 | Dia. of shot sleeve | mm | 60,70,80 |

| 10 | Dia.of Injection chamber flange | mm | 130 |

| 11 | Over height of flange | mm | 15-0.05 |

| 12 | Dosage of fluid metal pershot | kg | 5(Al.) |

| 13 | Projected area | cm | 283~1258 |

| 14 | Injection pressure | Mpa | 35~142 |

| 15 | Dry cycle | s | 10 |

| 16 | Oil tank capacity | L | 800 |

| 17 | Motor power | KW | 22 |

| 18 | Machine sizes(L*W*H) | M | 7.5×1.9×3.0 |

(Remark: 1.The die casting machine supplier keeps the right to revise above parameters, If there is any alterations, advance notice won't be given then. 2. Servo die casting machine can be choosed to save energy and cost. )

Die casting machine operator ladles the liquid Aluminum/Zinc/Copper alloy out from furnace, pure it into pressure casting chamber. Cold chamber die casting machine plunger inject the liquid metal alloy to pressure die with high pressure. Metal alloy solid, die open, the die casting parts be ejected out from mould cavities. A die casting injection process is finished, sprayer lubricates and cools the die cavites, mould close, and ready to start the next pressure die casting cycle.

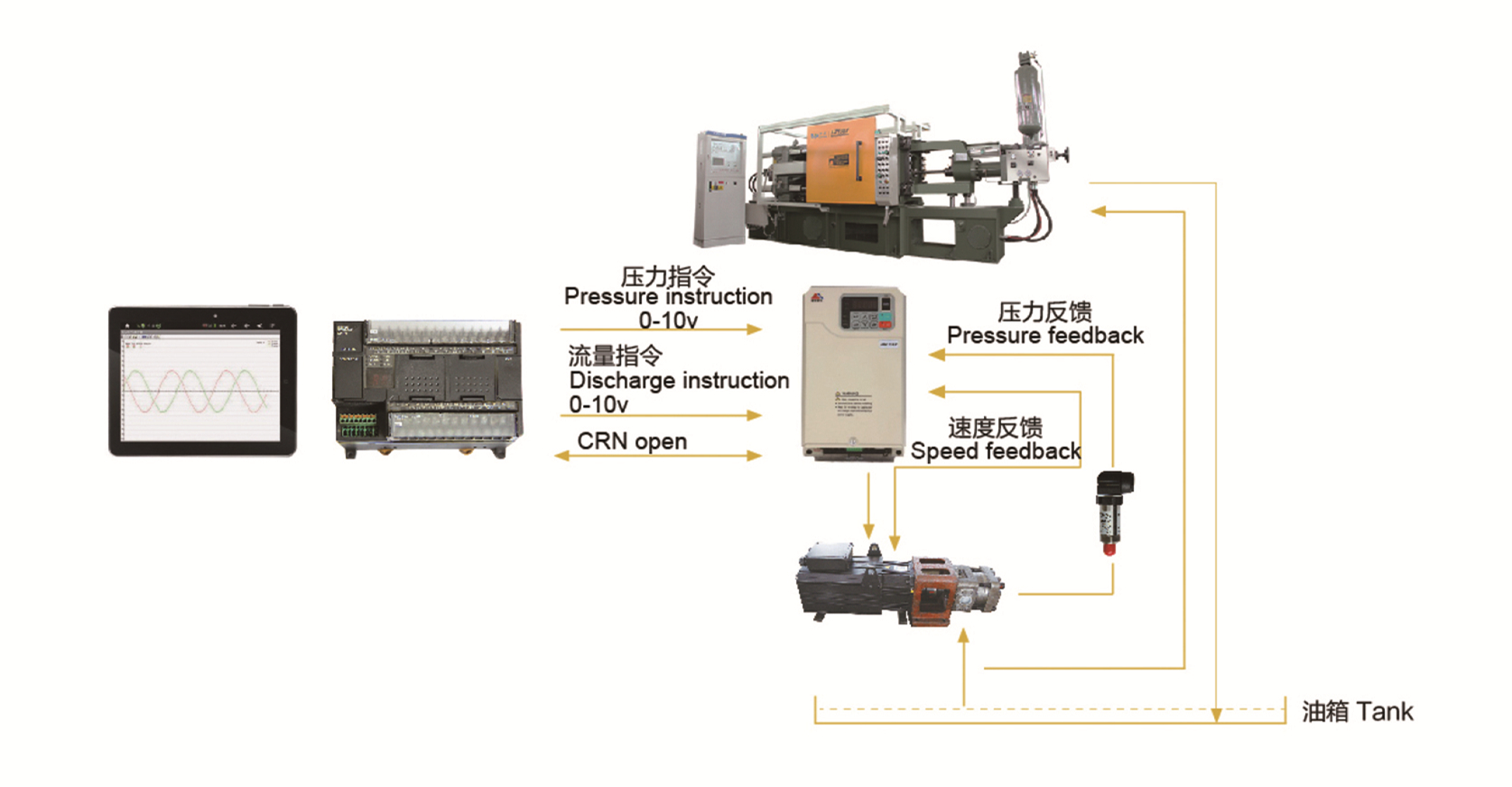

Servo driven system is an advisable choice for die casting machine factory. It features:

Energy saving

Rapid response and improved efficiency

Stable pressure and precision

High repetition accuracy

High speed and large lifting flow

Connection mode to improve heat dissipation performance

Auxiliary machines used to save labor or reach automatic die cast process.

Aluminum alloy melting furnace

Automatic ladling machine

Spraying Machine

Auto part off machine (Die casting parts pick-up machine / Extractor)

Technical information and prices of 400Ton PLC Horizontal High Pressure Die Cast Machine, Automatic ladling machine, Auto Spraying machine, Auto die cast parts pick-up machine and melting furnace, Please email: cnkylt@aliyun.com