Services Email: cnkylt@aliyun.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Tonnage: | |

|---|---|

| Type: | |

| Size: | |

| Usage: | |

| Original: | |

| Shipping Port: | |

| Lead time: | |

| Availability: | |

700 TON

LZ

8454301000

| No. | ITEM | UNIT | LZ700 |

| 1 | Clamping Force | KN | 7000 |

| 2 | Inner space between tie bars(H*V) | mm | 830×830 |

| 3 | Die Stroke | mm | 820 |

| 4 | Die Thickness | mm | 350~900 |

| 5 | Ejection Stroke | mm | 200 |

| 6 | Ejection Force | KN | 316 |

| 7 | Injeciton Force | KN | 235~680 |

| 8 | Injection position(enter is "0",down is "-") | mm | 0,-250 |

| 9 | Dia. of shot sleeve | mm | 80,60,100 |

| 10 | Dia.of Injection chamber flange | mm | 165f7 |

| 11 | Over height of flange | mm | 15-0.05 |

| 12 | Dosage of fluid metal pershot | kg | 12.4(Al.) |

| 13 | Projected area | cm | 518~972 |

| 14 | Injection pressure | Mpa | 30~135.4 |

| 15 | Dry cycle | s | 13 |

| 16 | Oil tank capacity | L | 1200 |

| 17 | Motor power | KW | 37 |

| 18 | Machine sizes(L*W*H) | M | 8.6×2×3.3 |

(Remark: 1.The die casting machine supplier keeps the right to revise above parameters, If there is any alterations, advance notice won't be given then. 2. Servo die casting machine can be choosed to save energy and cost. )

PDF TYPE:

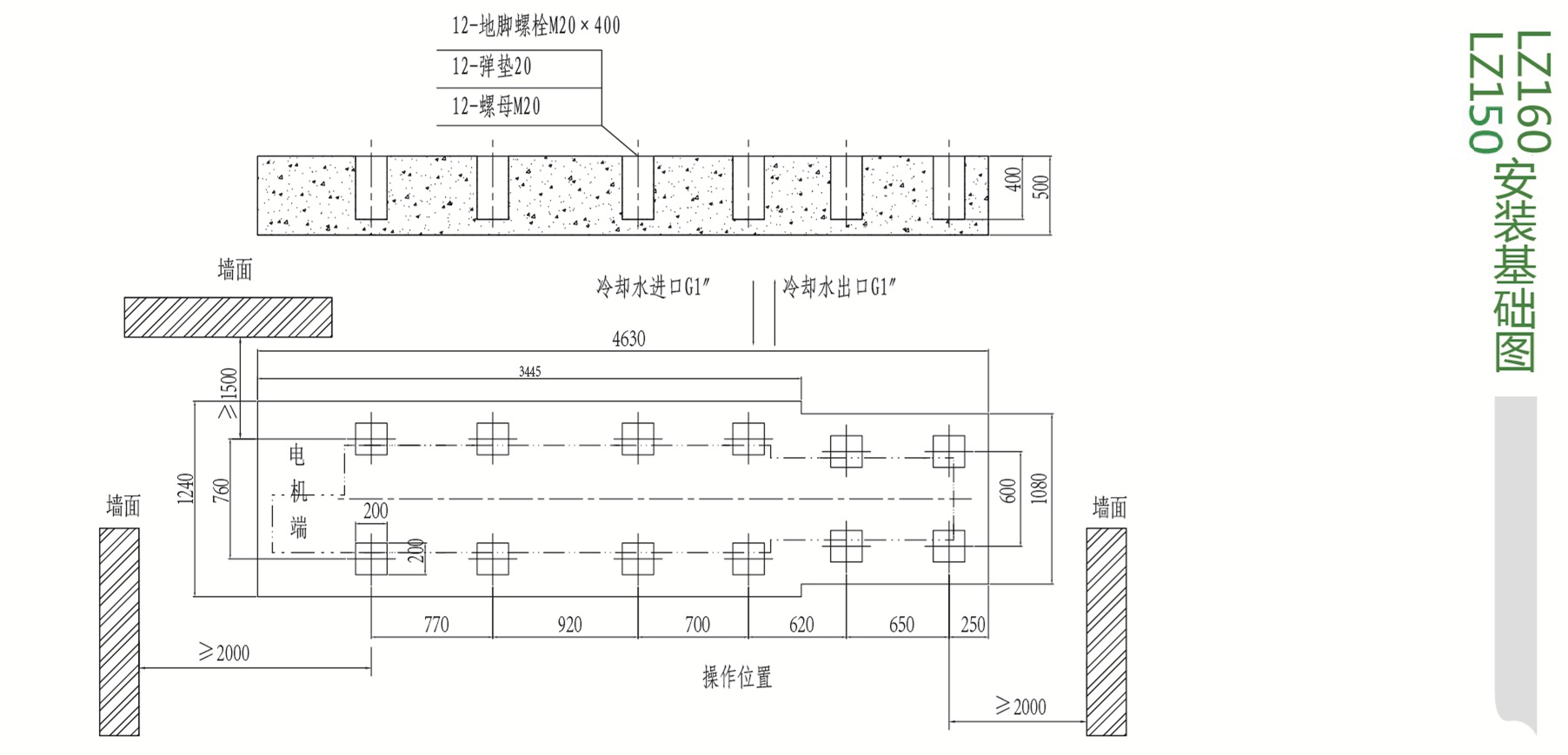

LZ150~LZ2000  LZ150LZ2000 cold chabmer die casting machine specifications and parameters.pdf

LZ150LZ2000 cold chabmer die casting machine specifications and parameters.pdf

JPG TYPE:

LZ150~LZ550  LZ150LZ550 cold chabmer die casting machine specifications and parameters.jpg

LZ150LZ550 cold chabmer die casting machine specifications and parameters.jpg

LZ700~LZ2000  LZ700LZ2000 cold chabmer die casting machine specifications and parameters.jpg

LZ700LZ2000 cold chabmer die casting machine specifications and parameters.jpg

| NO. | ITME | BRAND | REMARK |

| 1 | Hydraulic oil pump | HYTEK | CHINA |

| 2 | Magnetic valve、Electro-hydraulic valve | HYTEK | CHINA |

| 3 | Cooler | LONGTENG | Joint-venture |

| 4 | Lubrication equipment | LIUBIAN | CN-JP joint |

| 5 | PLC | OMRON | JAPAN |

| 6 | Contactor | SCHNEIDER | FRENCH |

| 7 | Touch screen | TouchWin | CANADA |

| 8 | Sealing system(glyd ring,step seal) | FIETZ | GERMANY |

| 9 | High-pressure hose | AEROQUIP | USA |

(Remark: Aluminum Molding Machine Spare parts brands can be changed as per customer demand. The producer of die casting machine-LZ (China) keeps the right to revise above parameters. If there is any alterations, advance notice won't be given then. Die Casting Machine spare parts brands can be changed as per customer demand.)

More information about our 7000Kn Cold Chamber Pressure Casting Machine Cost & Service, Please email us: cnkylt@aliyun.com

| No. | ITEM | UNIT | LZ700 |

| 1 | Clamping Force | KN | 7000 |

| 2 | Inner space between tie bars(H*V) | mm | 830×830 |

| 3 | Die Stroke | mm | 820 |

| 4 | Die Thickness | mm | 350~900 |

| 5 | Ejection Stroke | mm | 200 |

| 6 | Ejection Force | KN | 316 |

| 7 | Injeciton Force | KN | 235~680 |

| 8 | Injection position(enter is "0",down is "-") | mm | 0,-250 |

| 9 | Dia. of shot sleeve | mm | 80,60,100 |

| 10 | Dia.of Injection chamber flange | mm | 165f7 |

| 11 | Over height of flange | mm | 15-0.05 |

| 12 | Dosage of fluid metal pershot | kg | 12.4(Al.) |

| 13 | Projected area | cm | 518~972 |

| 14 | Injection pressure | Mpa | 30~135.4 |

| 15 | Dry cycle | s | 13 |

| 16 | Oil tank capacity | L | 1200 |

| 17 | Motor power | KW | 37 |

| 18 | Machine sizes(L*W*H) | M | 8.6×2×3.3 |

(Remark: 1.The die casting machine supplier keeps the right to revise above parameters, If there is any alterations, advance notice won't be given then. 2. Servo die casting machine can be choosed to save energy and cost. )

PDF TYPE:

LZ150~LZ2000  LZ150LZ2000 cold chabmer die casting machine specifications and parameters.pdf

LZ150LZ2000 cold chabmer die casting machine specifications and parameters.pdf

JPG TYPE:

LZ150~LZ550  LZ150LZ550 cold chabmer die casting machine specifications and parameters.jpg

LZ150LZ550 cold chabmer die casting machine specifications and parameters.jpg

LZ700~LZ2000  LZ700LZ2000 cold chabmer die casting machine specifications and parameters.jpg

LZ700LZ2000 cold chabmer die casting machine specifications and parameters.jpg

| NO. | ITME | BRAND | REMARK |

| 1 | Hydraulic oil pump | HYTEK | CHINA |

| 2 | Magnetic valve、Electro-hydraulic valve | HYTEK | CHINA |

| 3 | Cooler | LONGTENG | Joint-venture |

| 4 | Lubrication equipment | LIUBIAN | CN-JP joint |

| 5 | PLC | OMRON | JAPAN |

| 6 | Contactor | SCHNEIDER | FRENCH |

| 7 | Touch screen | TouchWin | CANADA |

| 8 | Sealing system(glyd ring,step seal) | FIETZ | GERMANY |

| 9 | High-pressure hose | AEROQUIP | USA |

(Remark: Aluminum Molding Machine Spare parts brands can be changed as per customer demand. The producer of die casting machine-LZ (China) keeps the right to revise above parameters. If there is any alterations, advance notice won't be given then. Die Casting Machine spare parts brands can be changed as per customer demand.)

More information about our 7000Kn Cold Chamber Pressure Casting Machine Cost & Service, Please email us: cnkylt@aliyun.com

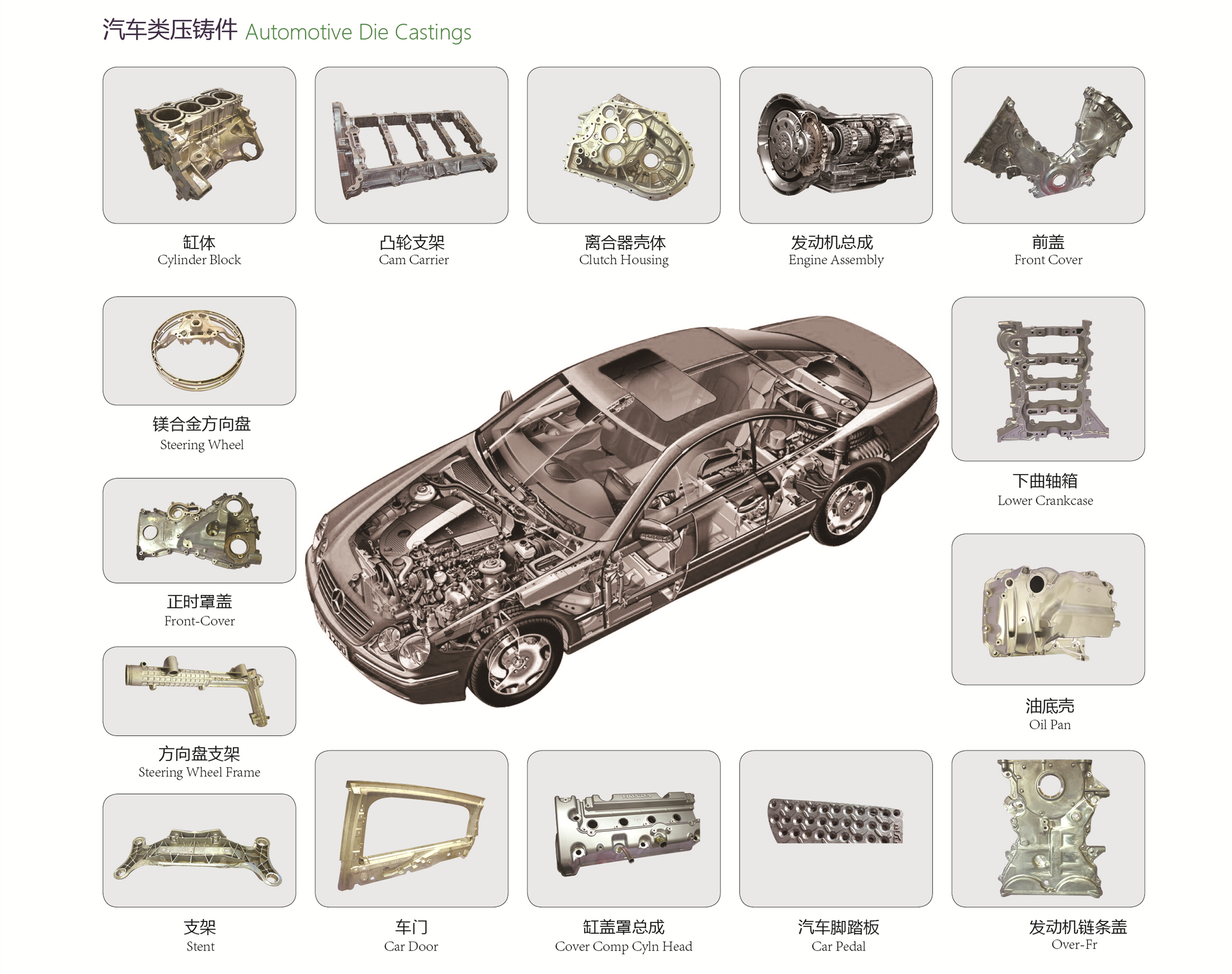

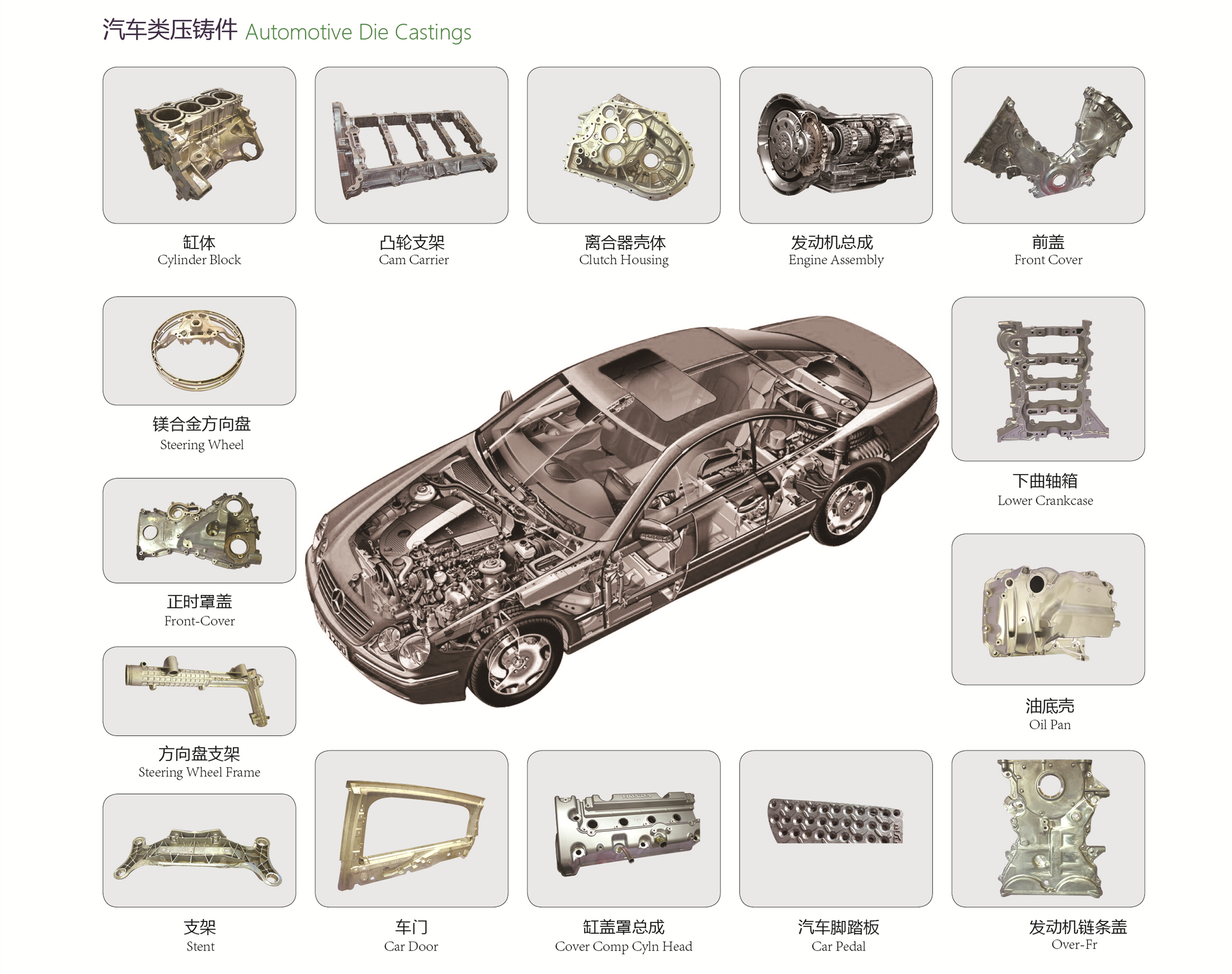

Automotive Die Casting Parts

Kitchen and Toilet Appliances Die Casting Parts

Lamps Die Casting Parts

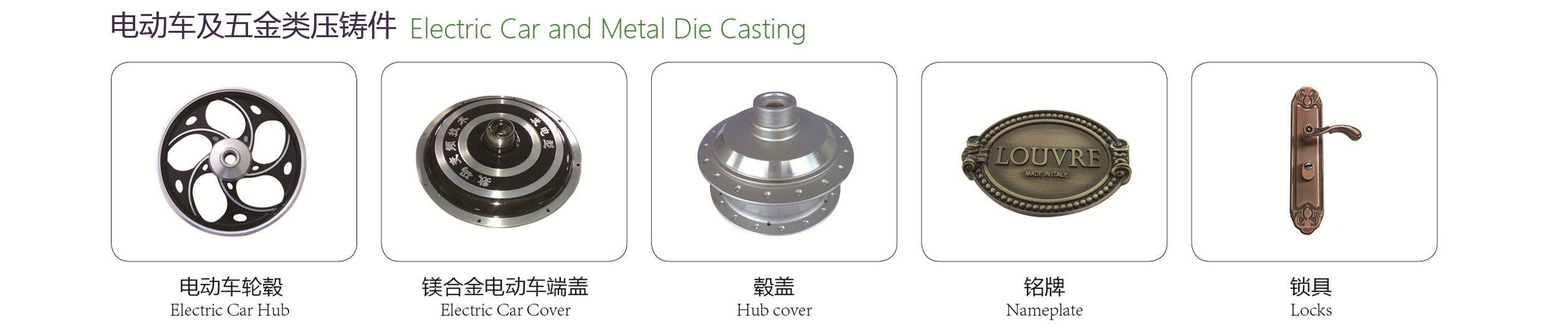

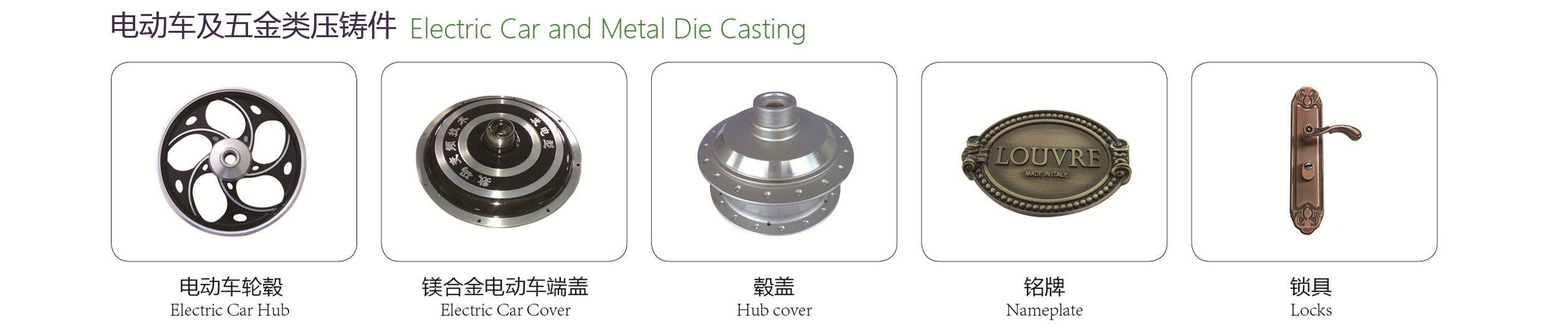

Electric Cars and Metal Hardware Die Casting Parts

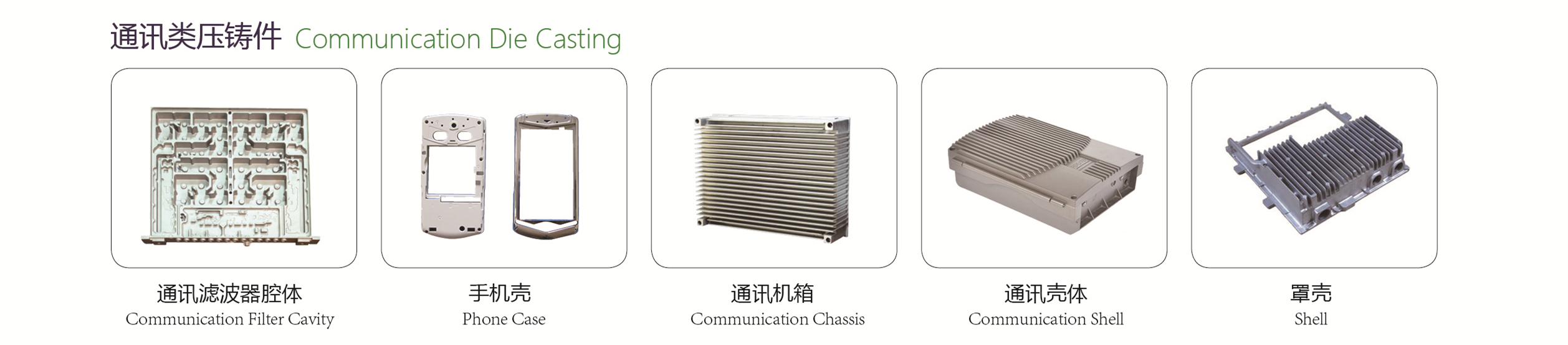

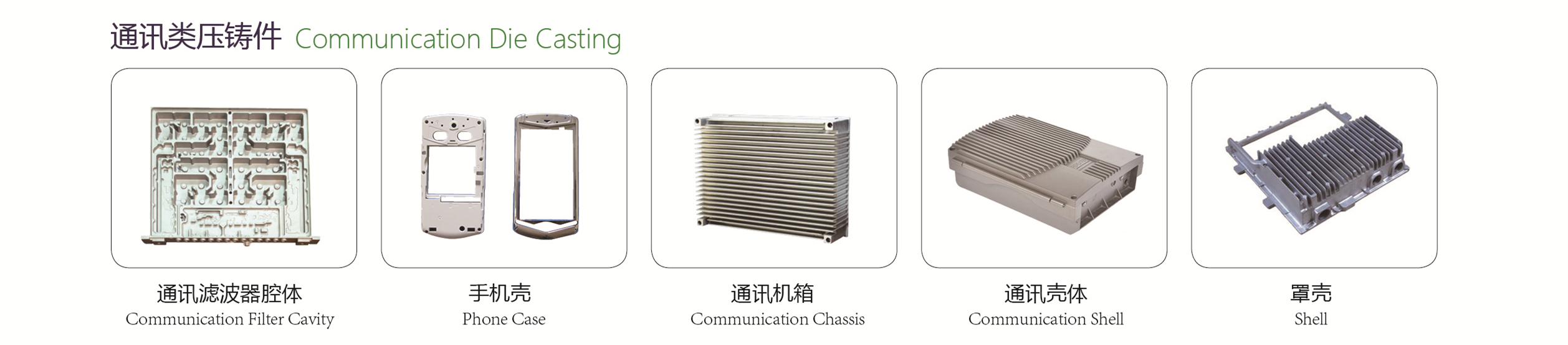

Tel-Communication Die Casting Parts

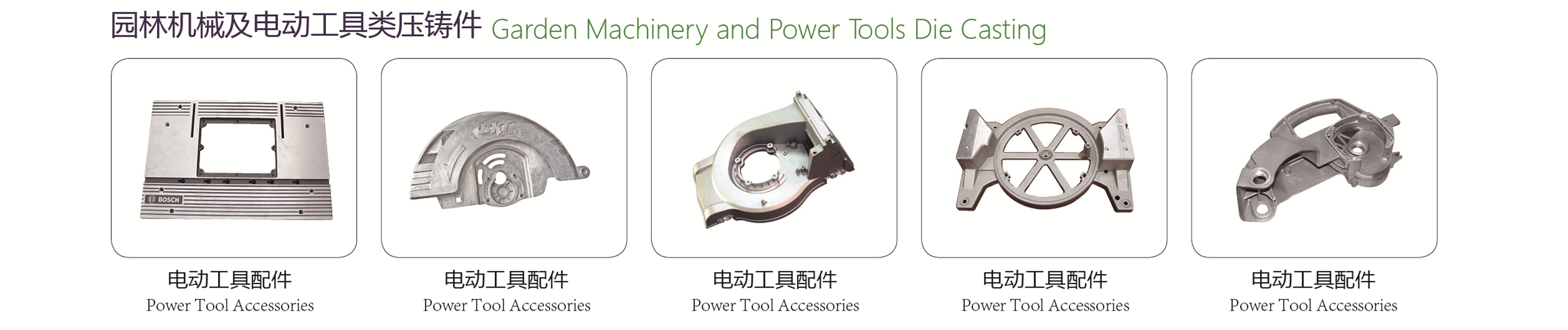

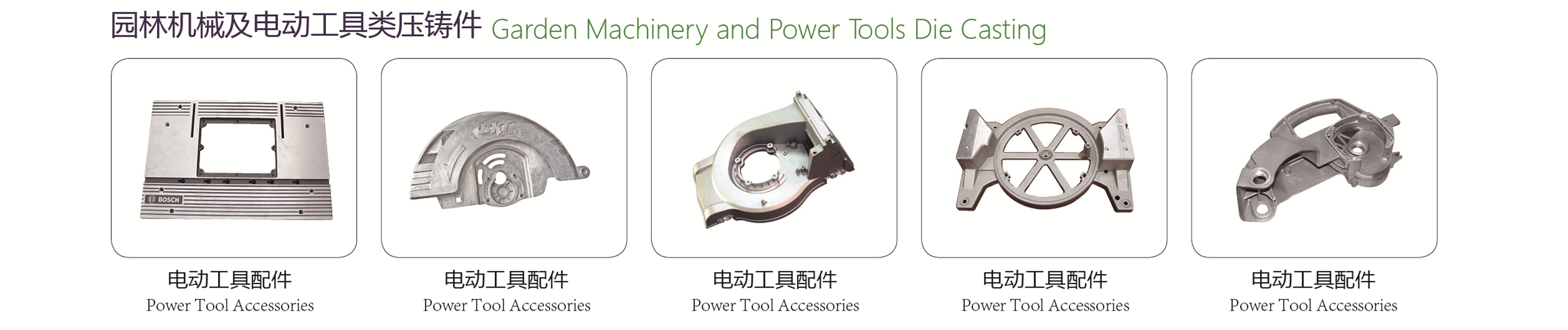

Garden Machinery and Power Tools Die Casting Parts

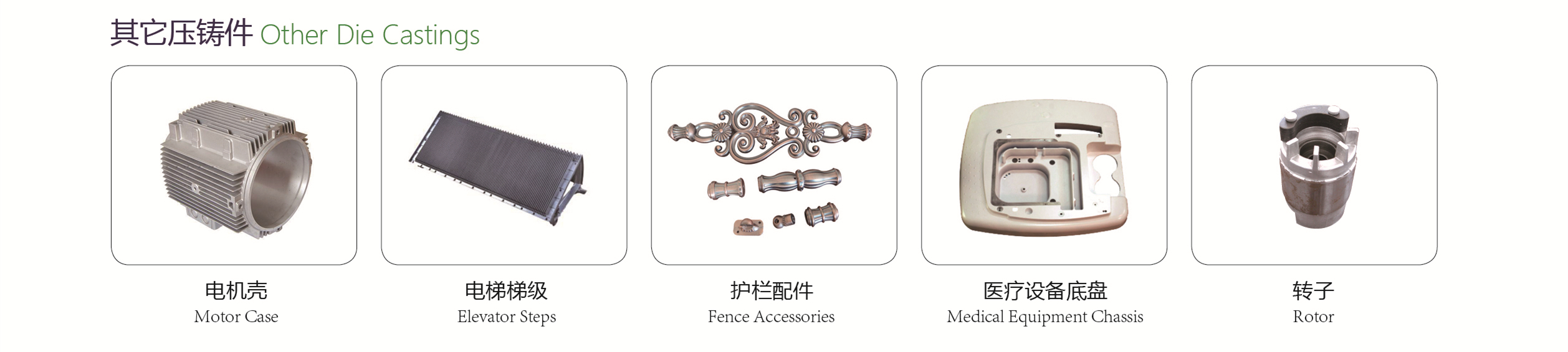

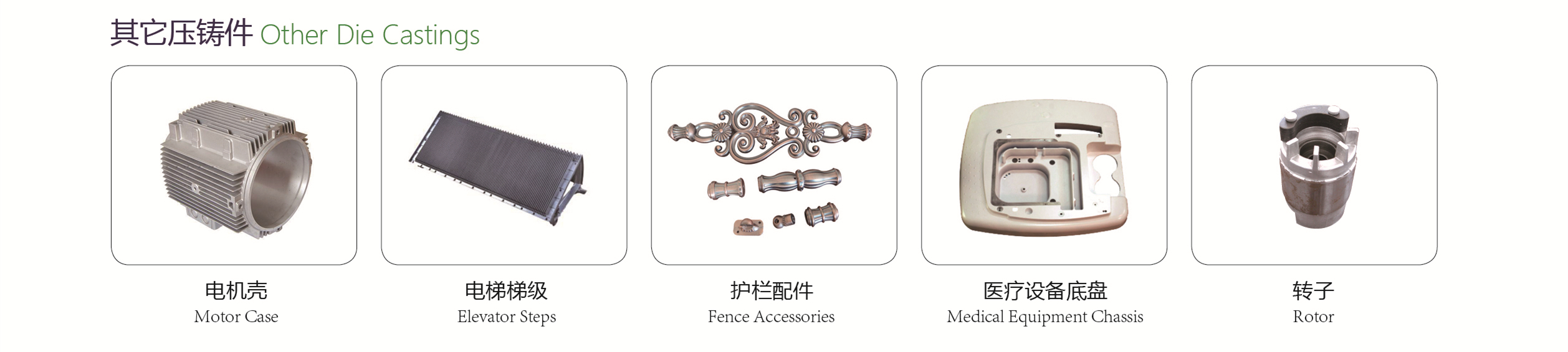

Other Die Casting Parts

Automotive Die Casting Parts

Kitchen and Toilet Appliances Die Casting Parts

Lamps Die Casting Parts

Electric Cars and Metal Hardware Die Casting Parts

Tel-Communication Die Casting Parts

Garden Machinery and Power Tools Die Casting Parts

Other Die Casting Parts

Provide pre-sales consultation such as investment budget and plant planning, so as to make the customer's plant design reasonable, standardized and save costs.

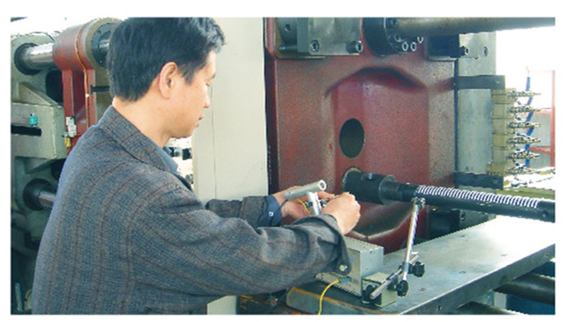

Continuous grounding resistance test

Injection speed test

Clamping force test

Electric control system test

Machine appearance inspection

Full load test for more than 72 hours

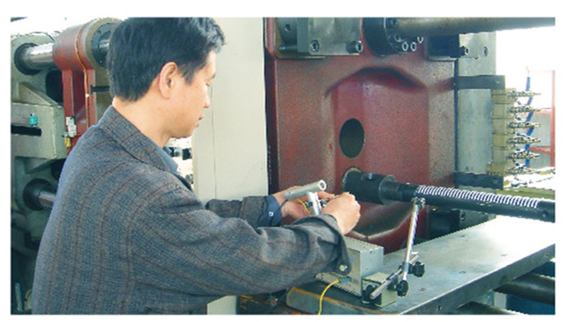

By guiding customers to install the water and electricity of die casting machines, adjusting new machines. Training customers' technicians and operators. The machine placement is standardized and reasonable. Enable relevant personnel to be familiar with the machine operation and maintance.

Provide FREE standard spare parts together with machine.

Install die casting machine.

Trainning Die casting operator.

Any questions be replied by email, video, photos within 24hr.

Engineer guide your operater to work and adjust machine by video on line.

Quality guarantee period: 12 months after machine put into operation.

If the equipment fails during the guarantee peirod, the manufacturer shall repair and replace accessories free of charge.

Provide pre-sales consultation such as investment budget and plant planning, so as to make the customer's plant design reasonable, standardized and save costs.

Continuous grounding resistance test

Injection speed test

Clamping force test

Electric control system test

Machine appearance inspection

Full load test for more than 72 hours

By guiding customers to install the water and electricity of die casting machines, adjusting new machines. Training customers' technicians and operators. The machine placement is standardized and reasonable. Enable relevant personnel to be familiar with the machine operation and maintance.

Provide FREE standard spare parts together with machine.

Install die casting machine.

Trainning Die casting operator.

Any questions be replied by email, video, photos within 24hr.

Engineer guide your operater to work and adjust machine by video on line.

Quality guarantee period: 12 months after machine put into operation.

If the equipment fails during the guarantee peirod, the manufacturer shall repair and replace accessories free of charge.