Services Email: cnkylt@aliyun.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Type: | |

|---|---|

| Material: | |

| Usage: | |

| Original: | |

| Shipping Port: | |

| Lead time: | |

| Service: | |

| Availability: | |

700

SJT

8454301000

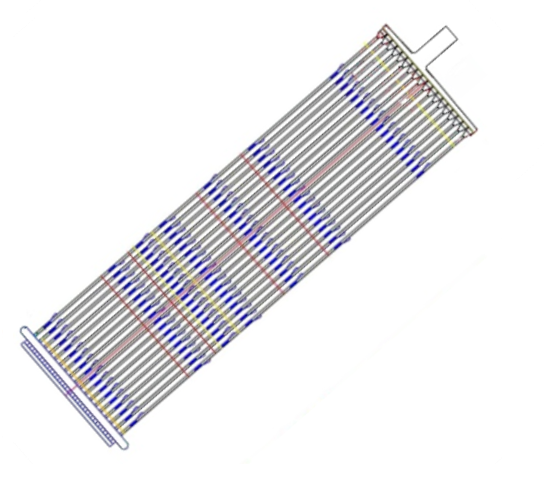

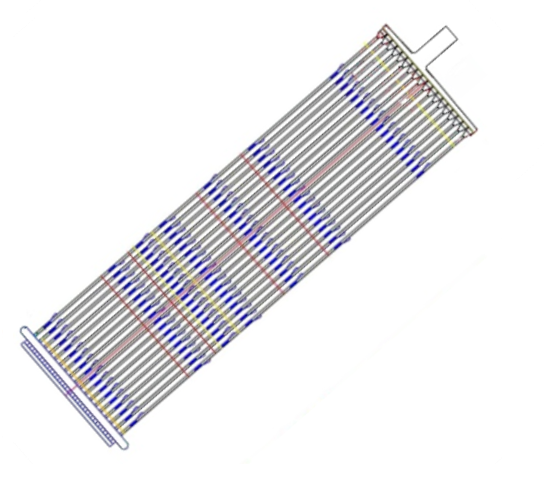

Lead Acid Battery Positive Grid Spine Pressure Die Casting Machine 700 Type used to manufacturer 2V lead acid battery tubular grids, forklift battery positive spines. Grid length max. is 630mm.

The pressure grid die cast machine process is automatic. Lead alloy feeding, casted grids pick up, and cutting is manual operated. Whole spine manufacturing has 2 process: grid die casting, casted spine cutting.

Grid length Max.: 630mm (2V battery, L<610mm. single palate)

Grid rib dia.: grid rib length 500mm, dia.≥3.0mm; grid rib length 630mm,dia.≥3.4mm

Grid width: Max.260mm

Melting pot capacity: 1800kg

System pressure: 21Mpa

Manufacturing Capacity: 2-3pieces/Min

Quality: Machine Qualified rate: 100%; Casting parts qualified rate: 95-100% (grids structure affect the qualified rate.)

Machine power: 45kw; Pressure air: 0.4-0.6MPa; Water pressure: 0.1MPa

Semi-auto control, auto injection, pick up grid by manual.

Use Famous brand hydraulic valves. Electrical control system has Semi-auto/Manual control.

With safety light curtain and safety switch to guarantee worker safe.

Electrical system adopts PLC control, with touch screen operation.

The heating of Lead alloy pot and mold by automatic control. Mold clamping platens and hydraulic system with cooling system.

Mold material: H13 or Customerzied.

Pot with dust cage,which can be connected with vent-pipe directly.

Cutting machine used to cut grid as per drawing requirement, one serious grid only adjust cutter to got different length, different serious grid need change cutter.

Timing heating function, process parameter password protection function.

Machine size: 4500mmx900mmx1700mm(TYPE700)

NO. | NAME | UN. | QTY | REMARK |

1 | Cylinder liner | PCS | 1 | |

2 | Nozzle(stainless steel) | PCS | 1 | |

3 | Plunger | PCS | 1 | |

4 | Plunger ring | PCS | 10 | stainless steel |

5 | Pot heating pipe | PCS | 1 | |

6 | Mold heating pipe | PCS | 2 | |

7 | Nozzle heating pipe | PCS | 10 | |

8 | Approach switch | PCS | 2 | |

9 | Pot thermocouple | PCS | 1 | |

10 | Nozzle thermocouple | PCS | 1 | |

11 | Mold thermocouple | PCS | 1 | |

12 | Mold locking Hydro-cylinder | SET | 1 | |

13 | Ejection Hydro-cylinder | SET | 1 | |

14 | Mold moving Hydro-cylinder | SET | 3 | |

15 | Injection Hydro-cylinder seal | SET | 3 | |

16 | Mold locking Hydro-cylinder seal | SET | 6 | |

17 | Ejection Hydro-cylinder seal | SET | 1 | |

18 | Steel tube connector seal | SET | 1 | |

19 | Pressure relay | PCS | 1 | |

20 | Temperature-controlled meter | PCS | 1 | |

21 | Intermediate relay | PCS | 10 |

Requirement: Ready 380V power, air pressure, cooling water, dust removal pipe. (Special power requirement should be point out when booking machine. Such as : In Peru, Machine will be adopt 220V,60HZ power.)

Related equipment: One set mold, Cutting machine and hoist for exchange mold is shipped together with grid die casting machine

Provide Mold release agency sample, can be used for one week.

Flat cement ground is required.

More information and price of Type 700 Battery Positive Spine/Grid Pressure Die Casting Machine, Mould or Production line, please contact us: cnkylt@aliyun.com

Lead Acid Battery Positive Grid Spine Pressure Die Casting Machine 700 Type used to manufacturer 2V lead acid battery tubular grids, forklift battery positive spines. Grid length max. is 630mm.

The pressure grid die cast machine process is automatic. Lead alloy feeding, casted grids pick up, and cutting is manual operated. Whole spine manufacturing has 2 process: grid die casting, casted spine cutting.

Grid length Max.: 630mm (2V battery, L<610mm. single palate)

Grid rib dia.: grid rib length 500mm, dia.≥3.0mm; grid rib length 630mm,dia.≥3.4mm

Grid width: Max.260mm

Melting pot capacity: 1800kg

System pressure: 21Mpa

Manufacturing Capacity: 2-3pieces/Min

Quality: Machine Qualified rate: 100%; Casting parts qualified rate: 95-100% (grids structure affect the qualified rate.)

Machine power: 45kw; Pressure air: 0.4-0.6MPa; Water pressure: 0.1MPa

Semi-auto control, auto injection, pick up grid by manual.

Use Famous brand hydraulic valves. Electrical control system has Semi-auto/Manual control.

With safety light curtain and safety switch to guarantee worker safe.

Electrical system adopts PLC control, with touch screen operation.

The heating of Lead alloy pot and mold by automatic control. Mold clamping platens and hydraulic system with cooling system.

Mold material: H13 or Customerzied.

Pot with dust cage,which can be connected with vent-pipe directly.

Cutting machine used to cut grid as per drawing requirement, one serious grid only adjust cutter to got different length, different serious grid need change cutter.

Timing heating function, process parameter password protection function.

Machine size: 4500mmx900mmx1700mm(TYPE700)

NO. | NAME | UN. | QTY | REMARK |

1 | Cylinder liner | PCS | 1 | |

2 | Nozzle(stainless steel) | PCS | 1 | |

3 | Plunger | PCS | 1 | |

4 | Plunger ring | PCS | 10 | stainless steel |

5 | Pot heating pipe | PCS | 1 | |

6 | Mold heating pipe | PCS | 2 | |

7 | Nozzle heating pipe | PCS | 10 | |

8 | Approach switch | PCS | 2 | |

9 | Pot thermocouple | PCS | 1 | |

10 | Nozzle thermocouple | PCS | 1 | |

11 | Mold thermocouple | PCS | 1 | |

12 | Mold locking Hydro-cylinder | SET | 1 | |

13 | Ejection Hydro-cylinder | SET | 1 | |

14 | Mold moving Hydro-cylinder | SET | 3 | |

15 | Injection Hydro-cylinder seal | SET | 3 | |

16 | Mold locking Hydro-cylinder seal | SET | 6 | |

17 | Ejection Hydro-cylinder seal | SET | 1 | |

18 | Steel tube connector seal | SET | 1 | |

19 | Pressure relay | PCS | 1 | |

20 | Temperature-controlled meter | PCS | 1 | |

21 | Intermediate relay | PCS | 10 |

Requirement: Ready 380V power, air pressure, cooling water, dust removal pipe. (Special power requirement should be point out when booking machine. Such as : In Peru, Machine will be adopt 220V,60HZ power.)

Related equipment: One set mold, Cutting machine and hoist for exchange mold is shipped together with grid die casting machine

Provide Mold release agency sample, can be used for one week.

Flat cement ground is required.

More information and price of Type 700 Battery Positive Spine/Grid Pressure Die Casting Machine, Mould or Production line, please contact us: cnkylt@aliyun.com