Services Email: cnkylt@aliyun.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Type: | |

|---|---|

| Material: | |

| Usage: | |

| Original: | |

| Shipping Port: | |

| Lead time: | |

| Mold service: | |

| Availability: | |

T500, T700

SJT

8454301000

Lead acid battery positive Spine/Grid Production Line is used to produce the tubular lead acid battery positive spine. The manufacturing process involves spines casting and spines cutting. A positive spine die casting machine, spine die casting mould and a spine cutting machine be used in the whole production process.

Lead alloy be feed into melting pot by manual. Electric heating tubes melting alloy in pot. Molten PB metal be inject into gird mould automatically. Operator picks casted grid from mold cavity. Use cutting machine to cut the gird runner and length to required dimension.

Conveyor belt feeds PB alloy blocks to melting furnance. Grid die casting machine inject grids. Then a robot pick the grid up from mold cavity, and set it in a storage frame. Another robot move the grid to cutting machine, and got a finished lead grid part. Whole process is full automatically.

In spine manufacturing process, we suggest use manual production line. It is more cheap, fast and easy maintain than automatic line.

Electric heating tubes used to melt PB alloy. First time, we need used burner to melt the Lead alloy blocks to avoid the damage of electric heater. Or, ladling molten alloy into machine pot from centralized smelting furnace. Melting temperature can be controlled and adjusted. A dust exhaust hood used to remove waste gas.

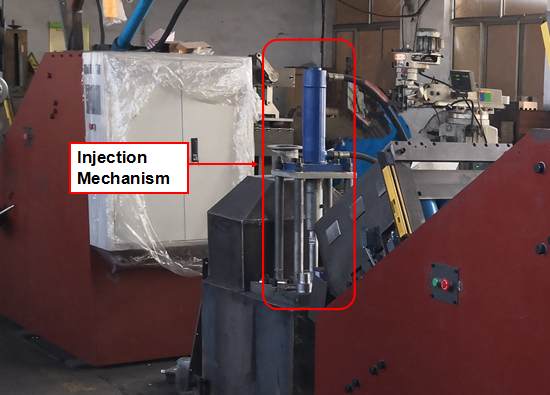

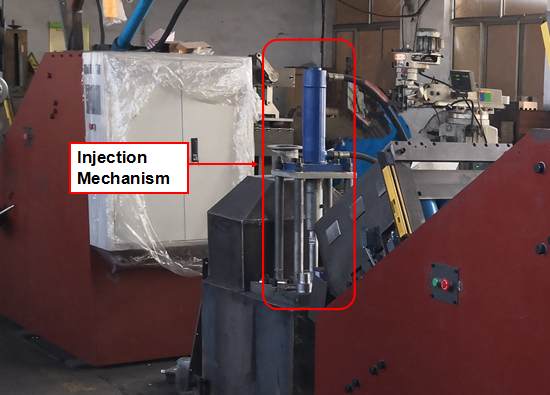

A longer hydraulic cylinder push and pull the grid mould up and down along the slant guide rail. Mold locking mechanism clamp the grid mold. Mould gate connect with injection nozzle tightly.

A hydraulic cylinder with a plunger be set above the furnance. Plunger push molten lead alloy through gooseneck mechanism to nozzle and be inject into mold cavities.

Longer cylinder pull the grid mold up, mold-opening mechanism open the movable die half.

Manual grid making process, operator pick casted spine up from mold cavity. Clean and lubricate mold cavity.

Casted grid be set in cutting machine. A fixture hold and limit the grid. Cutter move down, runner way and extra ribs be cut, got finished spine.

The finished grid be insert into tubes by manual.

PDC-pressure spine die casting machine, which used to cast tubular positive plates grid/spine for lead acid battery. High pressure makes the gird with high-density. That allows the casted grid has good performance.

Die casting lead alloy types: Lead antimony alloy, Lead calcium alloy.

Grid Mold 20days, Spine Die Casting Machine 30-40days.

Grid Die Casting Mold Material: H13 or same type mold steel material.

Mold life: 3-5years

PDC-T500 serious, PDC-T700 serious

(Free provide one set grid mold and one set cutting machine for a production line. )

Spine length (mm) | Spine dia.(mm) | Pot capacity (kg) | Power(KW) | |

PDC-T500 | 2v 15tube Single: L≤430mm; Double: L≤470mm | ≥3mm | 1800 kg | 45KW |

12v EV Single: L≤300mm; Double: L≤210mm | ≥2mm | |||

PDC-T700 | ≤630mm | Spine L 500mm≥3.0mm, 630mm≥3.4mm; EV≥2.0mm | 1800 kg | 45KW |

1. Choose suitable machine type and making mold as per customer grid drawings.

2. Provide solution, help client to solve problems encountered in production. As per customer demand to improve machine and mold design.

3. Machine and mold, from steel cutting, welding, assembly etc, all processes finished in house.

4. Test machine and mold in house, any problems can solve in factory directly and immediately. Machine and mold test videos are allowed.

5. Free grids samples to buyer for checking.

6. Provide machine & mold operation manual and videos.

7. Provide machine & mold disassembly and packing videos.

8. All disassembly structure parts be marked, easy for assembly in your local factory.

9. Machine be set on a flat cement ground is enough, ready air pressure, cooling water and power. Don't need make special treatment for cement ground.

10. Provide service by videos and online operation guide by computer. (the engineer can indicate

your engineer to operate machine in English.)

More information and price of Lead Acid Battery Positive Spine/Grid Pressure Production line: Die Casting Machine, Mould, please contact us: cnkylt@aliyun.com

Lead acid battery positive Spine/Grid Production Line is used to produce the tubular lead acid battery positive spine. The manufacturing process involves spines casting and spines cutting. A positive spine die casting machine, spine die casting mould and a spine cutting machine be used in the whole production process.

Lead alloy be feed into melting pot by manual. Electric heating tubes melting alloy in pot. Molten PB metal be inject into gird mould automatically. Operator picks casted grid from mold cavity. Use cutting machine to cut the gird runner and length to required dimension.

Conveyor belt feeds PB alloy blocks to melting furnance. Grid die casting machine inject grids. Then a robot pick the grid up from mold cavity, and set it in a storage frame. Another robot move the grid to cutting machine, and got a finished lead grid part. Whole process is full automatically.

In spine manufacturing process, we suggest use manual production line. It is more cheap, fast and easy maintain than automatic line.

Electric heating tubes used to melt PB alloy. First time, we need used burner to melt the Lead alloy blocks to avoid the damage of electric heater. Or, ladling molten alloy into machine pot from centralized smelting furnace. Melting temperature can be controlled and adjusted. A dust exhaust hood used to remove waste gas.

A longer hydraulic cylinder push and pull the grid mould up and down along the slant guide rail. Mold locking mechanism clamp the grid mold. Mould gate connect with injection nozzle tightly.

A hydraulic cylinder with a plunger be set above the furnance. Plunger push molten lead alloy through gooseneck mechanism to nozzle and be inject into mold cavities.

Longer cylinder pull the grid mold up, mold-opening mechanism open the movable die half.

Manual grid making process, operator pick casted spine up from mold cavity. Clean and lubricate mold cavity.

Casted grid be set in cutting machine. A fixture hold and limit the grid. Cutter move down, runner way and extra ribs be cut, got finished spine.

The finished grid be insert into tubes by manual.

PDC-pressure spine die casting machine, which used to cast tubular positive plates grid/spine for lead acid battery. High pressure makes the gird with high-density. That allows the casted grid has good performance.

Die casting lead alloy types: Lead antimony alloy, Lead calcium alloy.

Grid Mold 20days, Spine Die Casting Machine 30-40days.

Grid Die Casting Mold Material: H13 or same type mold steel material.

Mold life: 3-5years

PDC-T500 serious, PDC-T700 serious

(Free provide one set grid mold and one set cutting machine for a production line. )

Spine length (mm) | Spine dia.(mm) | Pot capacity (kg) | Power(KW) | |

PDC-T500 | 2v 15tube Single: L≤430mm; Double: L≤470mm | ≥3mm | 1800 kg | 45KW |

12v EV Single: L≤300mm; Double: L≤210mm | ≥2mm | |||

PDC-T700 | ≤630mm | Spine L 500mm≥3.0mm, 630mm≥3.4mm; EV≥2.0mm | 1800 kg | 45KW |

1. Choose suitable machine type and making mold as per customer grid drawings.

2. Provide solution, help client to solve problems encountered in production. As per customer demand to improve machine and mold design.

3. Machine and mold, from steel cutting, welding, assembly etc, all processes finished in house.

4. Test machine and mold in house, any problems can solve in factory directly and immediately. Machine and mold test videos are allowed.

5. Free grids samples to buyer for checking.

6. Provide machine & mold operation manual and videos.

7. Provide machine & mold disassembly and packing videos.

8. All disassembly structure parts be marked, easy for assembly in your local factory.

9. Machine be set on a flat cement ground is enough, ready air pressure, cooling water and power. Don't need make special treatment for cement ground.

10. Provide service by videos and online operation guide by computer. (the engineer can indicate

your engineer to operate machine in English.)

More information and price of Lead Acid Battery Positive Spine/Grid Pressure Production line: Die Casting Machine, Mould, please contact us: cnkylt@aliyun.com